|

| |

TM 5-4210-220-34

2-12.

PUMP DRIVE AND PTO - Continued

2-12.3

Reducer Gear to Pump Drive Shaft.

This task covers

Repair

TOOLS

MATERIALS/PARTS

Shop Equipment, Automotive

10, Appendix B Dry Cleaning Solvent

Maintenance and Repair,

16, Appendix B Grease

NSN 4910-00-754-0705

EQUIPMENT CONDITION

Reducer Gear to Pump Drive Shaft Removed (see

TM 5-4210-220-12)

REPAIR

NOTE

Reducer gear to pump drive shaft repair is limited to replacement of universal joints.

If drive shaft slip joint or tight end are damaged in any way, replace the complete drive shaft

assembly including the universal joints.

(1)

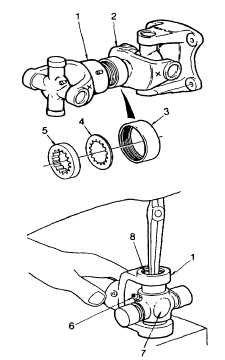

Mark slip joint (1) position before separating to

ensure alinement of components during

assembly.

(2)

Unscrew dust cap (3) from slip joint (1) and

separate slip joint (1) from tight end (2).

(3)

Remove the cork washer (5), steel washer (4),

and dust cap (3) from the tight end (2).

(4)

Wipe excess grease from tight end (2), and

slip joint (1), and inspect splines for damage

such as wear, pitting, rolling, peening and

fatigue cracks.

(5)

Evidence of damage of any kind is cause for

rejection. Replace complete drive shaft

assembly. If no damage is found, continue

with step 6.

(6)

Remove grease fittings (6) from cross (7).

(7)

Remove two snap rings (8) from tight end (1).

NOTE

Universal joint removal procedure will be similar for both the slip joint yoke (1) or the tight end yoke

(2) except the tight end yoke also has a flanged yoke. This means that for tight end universal joint

removal the following procedure will be carried out twice.

2-82

|