|

| |

TM 5-4210-220-34

2-12.

PUMP DRIVE AND PTO - Continued

2-12.3

Reducer Gear To Pump Drive Shaft - Continued

(16)

Using dry cleaning solvent (item 10, Appendix B), wash universal joint cross (7) and bearing caps (9).

WARNING

Death or serious injury could occur if compressed

air is directed against the skin. Do not use

compressed air for cleaning or drying unless the

pressure is/has been reduced to 30 psi (2.11

kg/cm2) or less. When working with compressed

air always use chip guards, eye protection and

other personal protective equipment.

(17) Dry components using compressed air. Blow

out grease passages in the cross (7).

(18) Apply a small amount of grease (Item 16,

Appendix B) to each bearing cap needle

bearing.

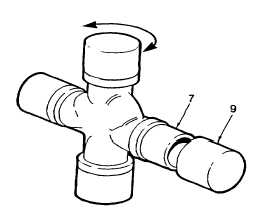

(19) Install and test bearing cap (9) on cross (7) journals as shown. The movement must be smooth and

resistance free.

(20) If any one component fails testing, the complete universal joint must be replaced.

NOTE

Universal joint installation procedures will be similar for both the slip joint yoke (1) or the tight end yoke

(2) except the tight end yoke also has a flanged yoke. This means that for tight end universal joint

installation the following procedure will have to be carried out twice.

(21) Tilt the cross (7) and install one journal into slip joint yoke hole.

(22) Allow one journal of the cross (7) to protrude

through the yoke hole. Install a bearing cap

(9) onto the protruding cross journal and

press in handtight.

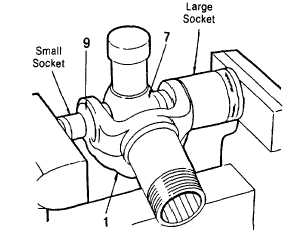

(23) Use shop vise as a press. Place the slip joint

yoke (1) between the vise jaws and begin to

close the vise. Continue to tighten the vise

until the bearing cap (9) is flush with the

yoke lug.

(24) Allow the opposite arm of the cross (7) to

protrude through the other slip joint yoke

hole. Install a bearing cap (9) onto the

protruding

cross

journal

and

press

in

handtight.

2-84

|