|

| |

TM 5-4210-220-34

3-8.

ENGINE Continued

3-8.3

Blower Continued

NOTE

When installed, the inside flats of the

sleeve will be parallel to the center line

of the housing.

(72) Lubricate the oil seal rings in the carriers on

the rotor shaft with engine oil (Item 17,

Appendix B).

(73) Position each oil seal rings in Its carrier so

the ring protrudes from its groove the same

amount on each side.

(74) Position the rear end plate (7) over the top

of the rotor shafts with the inner face of the

end plate facing the rotors and the TOP

side of the end plate facing the top side of

the blower housing.

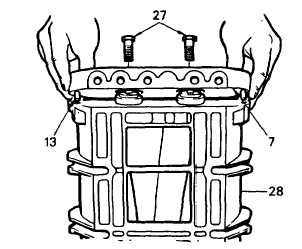

(75) Lower the end plate (7) straight over the rotor shafts until the dowel pins (13) in the end plate contact the

blower housing (28). Then, carefully work the dowel pins into the dowel pin holes in the housing and the oil

seal rings into the collars. Push the end plate tight against the housing (28). If necessary, tap the end plate

lightly with a plastic hammer.

(76) Insert the two fillister head screws (27) through the rear end plate (7) and thread them into the housing (28).

Tighten the screws to 10 ft lb (14 Nm). Do not use lockwashers on these screws.

(77) Check the relationship of the blower end plates to the housing at the cylinder block side of the blower

assembly. The protrusion of the housing with respect to the end plates should not be more than 0.0005 in.

(.013 mm) above to 0.0065 in. (0.165 mm) below the end plate. Excessive protrusion could distort the

housing when the end plate to cylinder block bolts are tightened and cause rotor to housing interference.

NOTE

To install the ball bearings on the rotor shafts and in the end plate, carry out steps 78 thru 81 following.

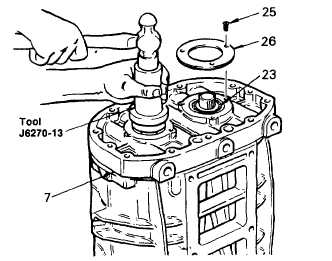

(78) With the blower still supported in a vertical

position on the two wood blocks, lubricate

one of the ball bearings (23) with engine oil

(item 17, Appendix B). Start the bearing,

numbered end up, straight on one of the

rotor shafts.

(79) Place installer J6270-13 on top of the

bearing and tap the bearing straight on the

shaft and into the rear end plate (7).

3-120

|