|

| |

TM 5-4210-220-34

3-8.

ENGINE Continued

(64) With the omitted serration in the splines of the shaft facing toward the top side of the end plate, start the end

of the rotor shaft into the right-hand shaft opening in the end plate so that the gap portion of the seal ring is

started into the ring collar. Continue to lower the rotor and very carefully apply pressure to the seal ring

approximately 180 deg. from the gap while gently working the seal ring into the collar until the rotor contacts

the end plate.

(65) Repeat steps 62 and 63 preceding to prepare the left-hand helix rotor (18).

(66) Position the rotors so the lobes are in mesh and the omitted serrations in the splines of both rotor shafts are

facing toward the top side of the end plate. Then install the left-hand helix rotor as detailed in step 64

preceding.

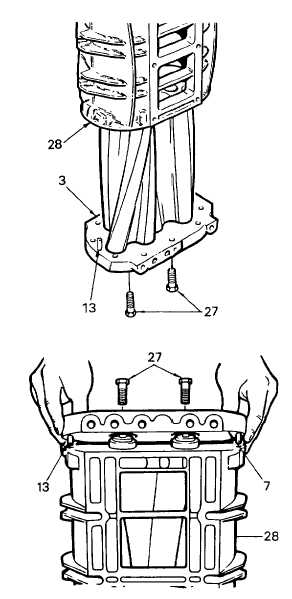

NOTE

To install the blower housing (28) over

the rotors (18 and 19) and attach to the

front end plate, carry out steps 67 thru

69 following. Make sure to aline the cast

triangle on the blower housing with the

same end plate as marked during

disassembly.

(67) Position the blower housing (28) over the

top of the rotors so the bottom face of the

housing faces the bottom side of the front

end plate (3). Then lower the housing over

the rotors until it contacts the dowel pins in

the end plate (3).

(68) Aline the dowel pin holes in the housing

with the dowel pins (13) in the end plate (3).

Then push the housing (28) tight against

the end plate. If necessary, tap the housing

lightly with a plastic hammer.

(69) Insert the two fillister head screws (27)

through the front end plate (3) and thread

them into the housing (28). Tighten the

screw to 10 ft lb (14 Nm). Do not use

lockwashers on these screws.

NOTE

To install the blower rear end plate on

the rotor shafts and housing, carry out

steps 70 thru 76 following.

(70) Check the dowel pins (13) project 0.320 in.

(8.13 mm) from the flat inner face of the

rear end plate (7) to

assure

proper

alinement of the end plate with the housing

(28).

(71) If removed, press a new bolt guide sleeve

(bushing) into one bolt hole in the bottom

side of the end plate. Install the sleeve, with

the three notches on the sleeve to the

bottom side of the end plate and the center

notch to the outside of the end plate, flush

to 0.005 in. (0.13 mm) below the surface of

the end plate.

3-119

|