|

| |

TM 5-4210-220-34

3-7.

TRANSMISSION-Continued

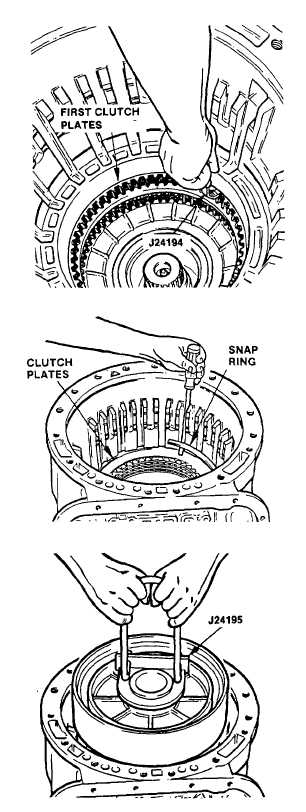

(4)

Using gage J24194, check the clearance

between the first clutch plates. It is

recommended

the

gage

be

placed

between the transmission housing and

the first steel plate. The prescribed

clearance is 0.095-0.145 in. (2.41-3.68

mm). Any dimension within 0.095-0.145

in.

(2.41-3.68

mm)

is

satisfactory.

Replace worn clutch plates with new

plates

to

establish

the

desired

clearance. Recheck the clearance.

ah.

Selection of Proper Center Support Snap

Ring

(1)

Install thirteen second clutch plates,

beginning with an external-tanged plate.

Alternately install seven external-tanged

plates and six internal-splined plates.

(2)

Retain the plates with the selective snap

ring. The snap ring should be color

coded white, 0.155-0.157 in. (3.94-3.99

mm).

(3)

The third-clutch piston was left from the

center support assembly during rebuild.

Install bracket J24195 into the recess

between the seal ring on the center

support hub.

(4)

Install

center

support

into

the

transmission housing. Be sure the

tapped hole in the support is alined with

the anchor bolt hole in the bottom of the

housing. Second clutch piston already

Inspected repaired and installed in

center support.

(5)

Remove lifting bracket J24195 from the

center support. Install a 3/8-16 x 3 in.

anchor bolt into the support through the

anchor bolt hole in the bottom of the

housing. Tighten the bolt fingertight.

(6)

Place the compressor sleeve J24208-2

on the hub of the center support. Place

compressor

J24208-3

across

the

transmission

housing.

Retain

the

compressor bar with two bolts.

(7)

Compress

the

center

support

by

applying a torque of 5 ft lb (6.8 Nm) to

the center screw J24208-1. Determine

the width of the snap ring opening, using

gage J33127. Gage lug thicknesses are

stamped on the tool shaft. Select one of

the snap rings in the following list.

Select the thickest snap ring that can be

put into the groove.

3-70

|