|

| |

TM 5-4210-220-34

3-7.

TRANSMISSION-Continued

ae.

Assembly of Complete Transmission After Overhaul

(1)

Coat the inside diameter of detent lever oil seal with petroleum jelly (item 21, Appendix B) and the outside

diameter with seal retainer sealant (item 26, Appendix B). Install the oil seal, lip first, into the

transmission housing. Use installer J26282 to properly locate the seal in the housing. The seal must

clear the chamfer in the housing.

(2)

Hold detent lever so that the selector valve pin extends toward the side of the housing. Slide the manual

shaft through the opening in the housing, oil seal, and slot in the detent lever. Install locknut and retainer

pin. Tighten the locknut to 20 ft lb (27 Nm).

(3)

Install new breather if removed. Torque to 16 ft lb (22 Nm).

(4)

Place transmission housing in a vertical position, rear upward.

NOTE

Two methods of checking clutch plate clearance

have been established. One method is by direct

measurement. The alternate method is by stack

dimension computation. Method one is detailed

following.

af.

First Clutch Installation

(1)

Beginning with an external-tanged clutch

plate

(24),

alternately

install

seven

external-tanged, and six internal-splined

(25) first clutch plates.

(2)

Install two guide bolts (180 deg. apart)

into the transmission housing. Aline and

install the adapter housing assembly

(14) and gasket (29).

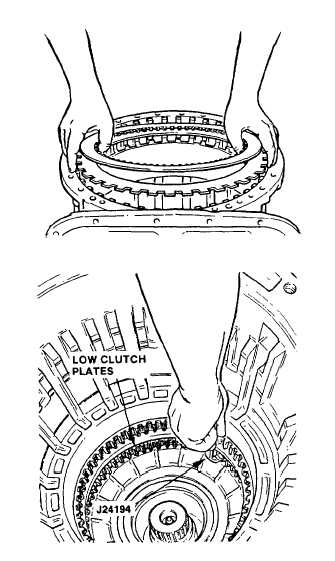

ag.

Low Clutch Installation

(1)

Beginning with an external-tanged clutch

plate, alternately install seven external-

tanged

and

six

internal-splined

low

clutch plates.

(2)

Install

the

rear

cover

assembly,

previously overhauled ready for final

assembly, and gasket onto the rear of

the transmission housing and secure it

with six’ 1/2 - 13 bolts and

lockwashers, evenly spaced. Tighten

the bolts to approximately 30 ft lb (41

Nm).

(3)

Invert the transmission, front upward.

Using gage J24194, check the clearance

between the low clutch plates. It is

recommended

the

gage

be

placed

between the adapter housing wall and

the first steel plate. The prescribed

clearance is 0.095 -0.145 in. (2.41 -3.68

mm). Any dimension within 0.095-0.145

in.

(2.41-3.68

mm)

is

satisfactory.

Replace worn clutch plates with -new

plates

to

establish

the

desired

clearance. Recheck the clearance.

3-69

|