|

| |

TM 5-4210-220-34

3-7.

TRANSMISSION - Continued

(12)

Lift off snap ring and remove the splined spacer Place tool J26598-A on a bench, face down, close the

jaws and remove the snap ring.

NOTE

If special tool J26598-A is not available, remove the snap ring with snap ring pliers. Do not scrape the

ground sleeve splines during removal.

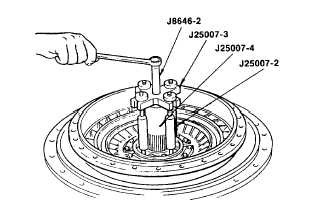

(13) Place puller sleeve J25007-4 onto the

converter ground sleeve.

(14) Insert the feet of leg and nut assemblies

J25007-2, between the balls of the bearing

assembly, spacing them 90 deg. apart.

(15) Rotate the legs to make the feet bear

against both the inner and outer bearing

race grooves.

(16) Install puller head tool J25007-3 onto the

legs, tightening the nuts evenly.

(17) Install center screw J8646-2 and tighten it by hand until it is centered on sleeve J25007-4. Hold the pump

assembly, and tighten the center screw until the pump assembly will lift off the ground sleeve.

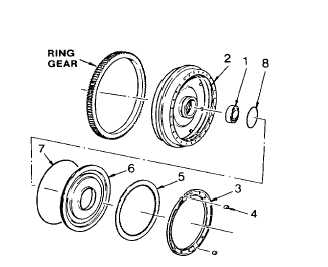

(18) Position flywheel assembly, ring gear side down, on workbench.

(19) Using two pry bars, cushioned

to

prevent scratching the parts, remove

the torque converter turbine from the

flywheel.

(20) Remove ball bearing (1) from the flywheel

assembly (2), only if replacement Is

necessary.

(21) Remove the lockup clutch backplate (3)

from the flywheel (2). Remove the keys (4)

from the flywheel bore.

(22) Remove the lockup clutch plate (5).

(23) Remove the lockup clutch piston (6).

Remove the seal ring (7) from the piston

outer groove. Remove the seal ring (8)

from the inner hub of the flywheel (2).

(24) If ring gear Is worn excessively, remove from flywheel.

(25) If the seal ring surface of the flywheel bore is worn beyond 1.007 in. (25.58 mm) diameter, rework is

necessary as detailed in c. following. Otherwise proceed to d. following

3-11

|