|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

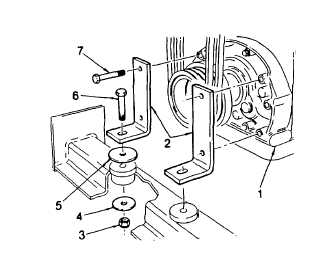

(20)

Tighten the engine mount-to-frame cross member capscrews (6) to 135 ft lb (180 Nm).

(21)

Tighten the crankshaft bolt to 180 ft lb (244

Nm).

(22)

Strike the end of the bolt with a sharp blow

using a 2 lb lead hammer.

(23)

Tighten the crankshaftbolt to 300 ft lb (407

Nm).

(24)

Strike the bolt again, with a sharp blow

using a 2 lb lead hammer.

(25)

Retighten the crankshaft bolt to 290 - 310 ft

lb (393 - 421 Nm). Do not strike the bolt

after the final torque has been applied.

The hex head of the crankshaft bolt may be used to bar, or turn, the crankshaft. However, the barring

operation should always be performed in a clockwise direction. It is very important to make certain that the

bolt has not been loosened during the barring operation. Otherwise, serious engine damage may result if

the or pulley is not securely fastened to the crankshaft.

(26)

Install oil pan as detailed in para. 2-19.11.

(27)

Install fan and drive belts, see TM 5-4210-220-12.

(28)

Install engine oil into crankcase, see LO 5-4210-220-12.

(29)

Start and run engine until it reaches operating temperature. Check for oil or coolant leaks, rattles or

vibrations and correct as necessary.

REPAIR

a.

Oil Pump Repair

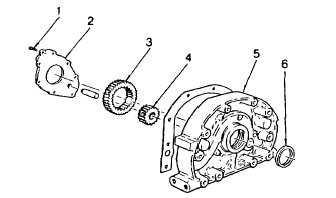

(1)

Remove the self-locking capscrews (1) that

secure the oil pump gear retaining plate (2)

to the crankshaft front cover (5). Separate

the retaining plate from the front cover.

(2)

Remove the oil pump drive gear (3), and

driven gear (4) from the crankshaft front

cover (5).

(3)

Support the outer face of the crankshaft

cover (5).

(4)

Using a hammer and a punch, drive the oil

seal (6) out of the crankshaft front cover.

2-233

|