|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

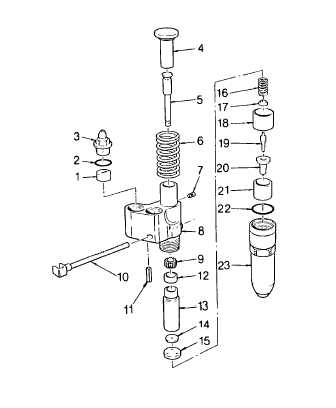

(3)

Raise the follower spring (6) with a screwdriver

above the lower land. Hold one hand on the

follower (4) and extract the stop pin (7). Allow

the spring to rise gradually.

(4)

Remove the follower (4), follower spring (6),

and plunger (5) as an assembly

(5)

Invert the injector on the holding fixture and

loosen the injector nut (23) using tool J4983-

01.

(6)

Lift the nut straight up, taking care not to

dislodge the spray tip and valve parts.

(7)

Remove the spray tip (20) and valve parts (19,

18, 17, 16, 15, 14) from the bushing and place

in a clean receptacle If the spray tip is lodged

in the nut, support nut on a wooden block and

drive the tip down through the nut using punch

J1291-02 and a hammer.

(8) Lift off the spill deflector (21) and then lift

bushing

(13)

straight

out

of

body

(8).

(9)

Remove the injector body from the holding fixture, invert and catch the gear retainer (12) and gear (9) as

they fall out of the body.

(10) Withdraw the injector control rack (10) from the body (8). Remove the seal ring (22) from the body.

b.

Inspect and Repair

NOTE

Most injector problems are the result of dirt particles. A clean work area is essential for parts cleaning and

inspection.

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard’s solvent) is potentially dangerous. Avoid repeated and

prolonged breathing of vapors and skin contact with the liquid. Do not use near open flame, arcing

equipment or other ignition sources. Always wear eye protection and protective clothing. The flash point

of P-D-680 is 100 to 138 deg. F (30 to 59 deg. C).

Death or serious injury could occur if compressed air is directed against the skin. Do not use compressed

air is directed against the skin. Do not use compressed air for cleaning or drying unless the pressure

is/has been reduced to 30 psi (2.11 kg/cm2) or less. When working with compressed air, always use chip

guards eye protection and other personal protective equipment.

2-185

|