|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

2-19.5

Injectors - Continued

(2)

Follow the test equipment manufacturers recommended test procedures and perform the

•

Injector Throughput Test

•

Injector High Pressure Test

•

Injector Pressure Holding Test

d.

Fuel Output Test

(1)

To check the fuel output, mount the injector in tester J22410 or similar model tester. Ensure the inlet

and outlet fuel lines are connected properly. If not the dirt on the inlet filter may be backwashed through

the injector. Be sure to install the injector exactly as the tool instructions detail.

e.

Needle Valve Tip Test

(1)

Using auxiliary tester J22640 and test J23010 or similar type equipment, perform needle valve tip test

following the tool manufacturers instructions

f.

Needle Valve Lift Test

(1)

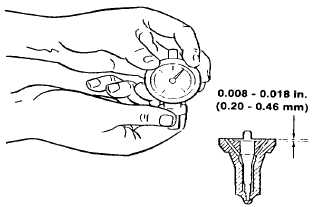

Place tool J9462-02 plunger on a flat

surface and zero the gage.

(2)

Place the needle valve in the spray tip.

(3)

Insert the quill of the needle valve in

the hole of the plunger of tool J9462-

02.

(4) Hold the spray tip land tight against the

gage. The dial should read 0.008 -

0.018 in. (0.20 -0.46 mm).

(5)

If it is greater than 0.018 in. (0.45 mm) replace the needle valve and tip. If it is less than 0.008 in. (0.20

mm) inspect spray tip seat or needle valve for foreign material. If the lift is satisfactory, test g. failed

because of a weak spring. Repeat test g. with a new spring or new spray tip assembly depending

which failed.

REPAIR

NOTE

Injector must be removed from truck. Before any repair can be carried out the injector must be

disassembled.

a.

Disassembly Prior To Repair

(1)

Clamp injector in injector holding fixture J22396.

(2)

Remove filter caps (3), gaskets (2), and filter (1). Discard the filter (inlet side only) and gaskets.

2-184

|