|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

2-19.5

Injectors - Continued

(1)

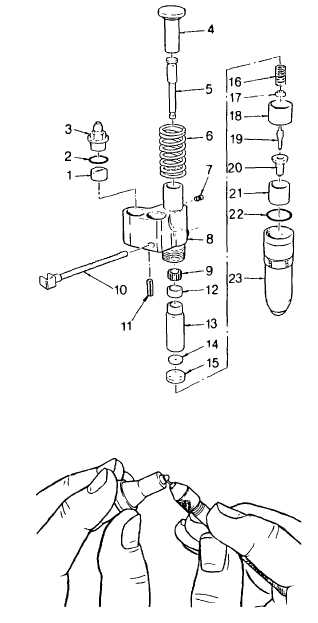

Wash all components In dry cleaning solvent

(item 10, Appendix B). Discard filter (1) and

seal ring (22). Dry all parts with compressed

air. Clean out all passages and drilled holes.

(2)

If there is carbon in the spray tip (20) soak in

methyl ethyl ketone (item 19, Appendix B) for

15 minutes. Clean the spray tip with tool

J24838. Be careful not to push too far and

contact the needle valve seat in the end of the

tip.

(3)

Clean the spray tip orifices with pin vise J4298-

1 and wire J21461-01 (0.006 in.). Before

using the wire, hone the end until free of burrs;

taper the end with stone J8170. Allow wire to

extend 1/8 in. beyond pin vise.

(4)

Buff the exterior of the spray tip with a brass

wire buffing wheel J7944. Hold the spray tip

with tool J24838. Lightly buff the tip end.

(5)

Clean and brush all passages in the body using

fuel hole brush J8152, and rack hole brush

J8150.

(6)

Insert reamer J21089 into the injector body

turning in a clockwise direction a few turns.

Check reamer contacts entire face of inner

ring. Repeat as required.

(7)

Clean up opposite end of the ring by inserting reamer J21089 in the other end of the body and repeating

step 6.

(8)

Insert a straight fluted 0.375 in. reamer inside the ring bore of the injector body and rotate clockwise to

remove any burrs in the ring. Wash and blow dry the injector body.

(9)

Carefully insert carbon remover J9418-5 into injector nut. Turn in clockwise direction a few turns.

Remove reamer rotating clockwise. Use care to minimize removing metal or setting up burrs on the

spray tip seat. Remove only enough metal to produce a clean uniform seat. Replace the nut if it is

severely damaged.

2-186

|