|

| |

TM 5-4210-220-12

4-18. PUMP, PIPING, AND VALVES - Continued

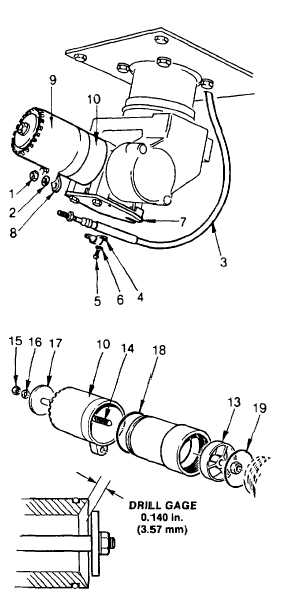

(9) Slide new cable (3) through base plate (18) from inside the truck. Lock into position using clamp (10),

lockwasher and screw (9). Tighten screw firmly.

(10) Thread ball joint (17) onto the cable end rod (15) the same number of turns as recorded in step 6

preceding. Tighten jam nut (16) firmly.

(11) Attach pattern control handle bracket (14) using screws (11), lockwashers (12), and nuts (13).

(12) Attach cable (3) to Z-plate (22) using U-bolt (21) and locknuts (20). Tighten locknuts firmly.

(13) Install nozzle end of cable (3) into water sleeve link (8) and attach using washer (2) and nut (1).

Tighten nut firmly.

(14) Set control handle to 'FOG' position.

Ensure water sleeve (18) is fully retracted

on the water tip (19).

(15) Attach cable (3) to mounting plate (7)

using conduit clamp (4) screws (5) and

lockwashers (6.

(16) Cycle control handle from 'FOG' to

'SOLID' a couple of times.

(17) Set control handle to 'FOG'. Cable

adjustment

is

satisfactory

if

zero

clearance is measured between water

sleeve (18) and tip assembly (19). If

adjustment is necessary repeat steps 15

thru 18 preceding.

c. Nozzle Repair

NOTE

This task can be completed with the

turret mounted on the truck.

(1) Remove nut (1) and lockwasher (2) from

nozzle end of cable (3).

(2) Remove conduit clamp (4) that holds cable

(3) to the mounting plate (7) by removing

screws (5) and lockwashers (6).

(3) Pull cable (3) out of water sleeve link (8).

(4) Carefully pull on water sleeve (9) until it

separates from the water tip (10).

(5) Unscrew the water tip (10) from the turret

head.

4-279

|