|

| |

TM 5-4210-220-12

4-15. AUXILIARY POWER UNIT - Continued

4-15.11 Engine Crankshaft and Camshaft - Continued

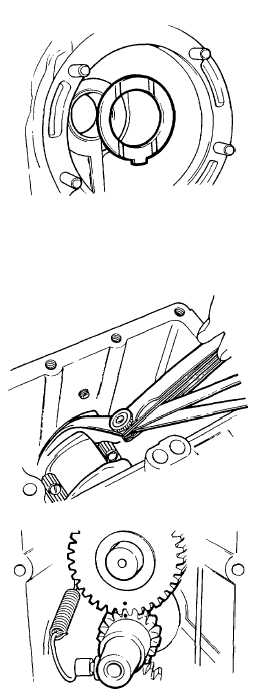

INSTALLATION

(1)

Install new oil seals in crankcase cover and

bearing end plate.

(2)

Install crankcase thrust washer on inner wall of

block. If necessary hold in place with white

grease (item 34, Appendix E).

(3)

Smear lubricating oil (Item 17, Appendix E) on

central bushing.

(4)

Carefully install crankshaft through bushing. Do

not damage bushing with crankshaft gear.

(5)

Smear lubricating oil (item 17, Appendix E) on

bearing end plate bushing.

(6)

Install second thrust washer over crank and push

bearing end plate over crankshaft. Ensure thrust

washer keys with end plate. Be sure oil seal is

not forced and therefore damaged.

(7)

Install two bolts in threaded holes of end plate.

(8)

Adjust

crankshaft

end

float

by

tightening/

loosening two bolts in end plate. End float

should be 0.004 - 0.008 in. (0.10 - 0.20 mm).

(9)

When end float is correct, measure end

plate/crankcase clearance. Select gasket(s) of

suitable thickness (Gaskets are available in

thickness of 0.004, 0.008, 0.0124, 0.016 in.

(0.10, 0.20, 0.30, 0.40 mm).

(10)

Remove bearing end plate and bolts. Place

selected gasket over end plate and install on

crankcase as detailed in step 6 preceding.

Tighten nuts to 22 ft lb (29 Nm). Check

crankshaft end play and readjust as required.

(11)

Lift hinged tappets and install camshaft into block

bore Match timing mark on crankshaft gear to

mark on camshaft gear

(12)

If timing marks are not marked on gears proceed

as in steps 13 and 14 following. Otherwise

proceed to step 15.

4-180

|