|

| |

TM 5-4210-220-12

4-15. AUXILIARY POWER UNIT - Continued

(13)

Place piston at top dead center..

(14)

Insert the camshaft with cams on

overlapping position (inlet starts to open-

exhaust just about to close). Check that

tappets are at the same height, otherwise

shift gear one tooth back or forward until

alinement of tappets is obtained.

(15)

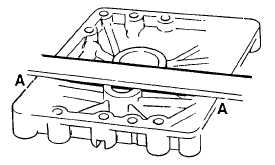

Lay straight edge across inside of

crankcase cover. The gasket surface of

housing should be on same plain as the

cover thrust surface for the crankshaft.

There should be no clearance at A.

Check with feeler gage. If there is

clearance, measure with feeler gage.

(16)

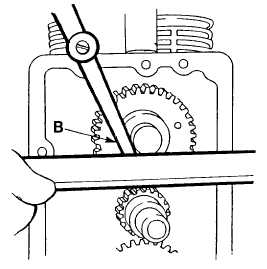

Support

engine

on

workbench

so

crankshaft and camshaft are positioned in

upright position.

(17)

Measure clearance B between straight

edge placed across block and thrust

surface of camshaft. Clearance B should

not be greater than 0.004 in. (0.10 mm).

(If

necessary

combine

clearance

measurements A and B).

(18) Select gasket(s) to give camshaft end play

of 0.004 - 0.012 in. (0.10 - 0.30 mm).

Gaskets are available in. 0.008, 0.012 in.

(0.20, 0.30 mm) sizes.

(19)

Coat crankshaft cover camshaft journal,

crankshaft needle bearing, and oil seal

with lubricating oil (item 17, Appendix E).

(20)

Install crankshaft cover using machine

screws. Be sure engine breather tube

clamp is installed with bottom left hand

screw.

4-181

|