|

| |

TM 5-4210-220-12

4-15. AUXILIARY POWER UNIT - Continued

NOTE

Difference between these measurements and

those in step 16 must be less than 0.004 in.

(0.10 mm). Replace camshaft or crankcase,

or crankcase cover as required.

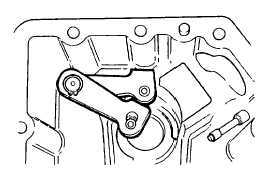

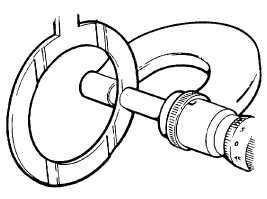

(18)

Insert crank into crankcase cover. Check for radial

movement between needle bearing and journal.

Replace bearing if movement is excessive using

puller 7070.3595.46. Replace bearing from crank

side of cover. Engraved side of bearing must be on

crank side of cover.

(19)

Check flange area of cover. Clean away all gasket

material. Remove any burrs or sharp edges with

emery cloth (item 13, Appendix E).

(20)

Remove valve tappet circlip and lift out both

tappets.

(21)

Inspect valve tappets. Diameter of pivot must be

between 0.370 - 0.378 in. (9.4 - 9.6 mm). Replace

as required.

(22)

Measure diameter of pivot hole in both tappets.

Hole must not be greater than (pivot diameter +

0.004 in. (0.1 mm)). Replace pivot or tappets as

required.

(23)

Check gap between tappet rollers and shaft. Gap

must be greater than 0.008 in. (0 2 mm). Replace

hinged tappet if necessary. Roller must roll freely

and not bind.

(24)

Install both tappets on pivot and replace circlip.

(25)

Inspect both crankshaft thrust washers for wear.

Replace if badly scored or if any measurement

indicates a thickness of less than 0.090 in. (2.31

mm)

4-179

|