|

| |

TM 5-4210-220-12

4-9 GENERAL MAINTENANCE PROCEDURES - Continued

4-9.4 General Repair/Assembly Instructions Continued

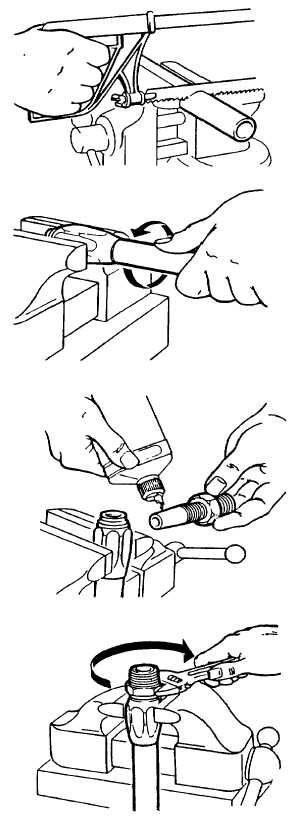

(4)

Using a cut-off saw or a fine tooth hacksaw cut

new hose square to length.

WARNING

Death or serious injury could occur if compressed

air is directed against the skin. Do not use

compressed air for cleaning or drying unless the

pressure is/has been reduced to 30 psi (2.11 kg/cm2)

or less. When working with compressed air always

use chip guards, eye protection and other personal

protective equipment.

(5)

Using compressed air, blow out shavings from

hose bore.

(6)

Clamp socket in vise. Thread new hose into

socket in a counterclockwise direction until it bottoms out,

then back out hose 1/4 turn.

(7)

Using hydraulic oil (item 9, Appendix E), liberally

lubricate nipple threads and inside of hose.

(8)

Insert nipple into hose and socket and tighten in

a clockwise direction. Leave 1/32 in. (1 mm) between nipple

hex and socket.

(9)

To prevent any contamination from new hose

assembly, blow out hose assembly using compressed air.

Rinse inside of hose with hot water. Do not allow water

temperature to exceed 180 deg. F (82 deg. C). Using

compressed air, blow out all water from hose assembly.

(10)

If hose assembly is not going to be installed

immediately after installing fittings, cap both ends to keep

hose clean.

4-66

|