|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

REASSEMBLY

Fuel Bowls and Metering Blocks

Refer to Fig. 28 for the correct location of the fuel bowl parts.

The primary and secondary fuel bowls and metering blocks

are installed on the main body in the same sequence.

Primary Fuel Bowl and Metering Block:

1. Using special socket SE-1772-1 install new gasket and

power valve assembly in metering body.

2. Install the two main jets using special tool SE-1772-6.

3. Where used, install "0" rings, using petroleum jelly as a

lubricant on accelerator pump fuel transfer tube and install

tube in metering block.

4. Install fuel bowl to metering block gasket to metering

block. Be sure all punchings are removed from gasket and

pump passage and gasket aligns with pump passage in

metering block.

5. Install fuel filter screen, fuel inlet fitting and new fuel inlet

fitting gasket.

6. Lubricate the tip of a new accelerator pump synthetic valve

(where used) with a small amount of petroleum jelly and insert

tip into accelerator pump cavity center hole. Using a pair of

needle nose pliers reach into the fuel bowl and grasp the valve

tip. Pull the valve in until it seats in the pump cavity wall and

cut off the tip at the retaining shoulder.

In some 4150 carburetor fuel pump cavities there will be a

very small bleed hole from the fuel bowl. This bleed hole

allows vapor pressure to escape from the fuel pump cavity

into the fuel bowl. This pressure bleed off prevents fuel spill

over through the fuel pump discharge nozzles. The bleed hole

must be checked to make sure it is not clogged.

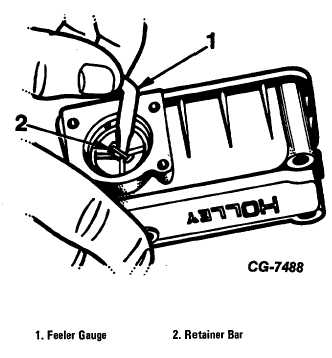

7. Where used, check accelerator pump inlet check ball travel

(Fig. 47). Clearance between ball and retainer bar is

specified at .011 to .017". Best operation can be expected

with clearance set at low end of specifications (.011"-.014").

Adjustment is made by bending retainer bar. If adjustment is

necessary, extreme care must be taken to prevent possible

damage to ball and/or seat.

Figure 47 Checking Accelerator Pump Inlet Check Ball

Clearance (Not used on All Carb.)

It is emphasized that the check ball setting mentioned above

is a critical item in obtaining instant pump response to throttle

movement. Ball travel in excess of .017" can easily cause a

lag in fuel injection with consequent engine falter during

throttle opening.

8. Position pump diaphragm spring in recess and install

diaphragm assembly. Note that the flat rivet head faces up.

Place pump diaphragm cover in position making sure the

holes are aligned. Install the four screws and lock washers.

Tighten them alternately to evenly compress the diaphragm.

9. Obtain new "O" ring and using petroleum jelly as a

lubricant slide "O" ring into groove on needle and seat

assembly. Install assembly in fuel bowl. Always use new

gasket between adjusting nut and fuel bowl and also between

lock screw and adjusting nut.

10. Insert fuel inlet baffle in bowl over needle and seat

assembly.

11. Place conical spring on locator of float lever and slide the

float with the spring onto shaft in fuel bowl. Secure with

retainer.

CGES-125-T Page 31

PRINTED IN UNITED STATES OF AMERICA

|