|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

REASSEMBLY

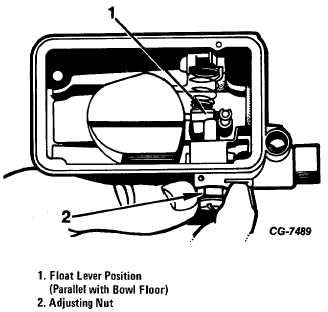

Figure 48 Bench Adjustment of Fuel Bowl Float

12. The float is made of cellular plastic material; its buoyancy

is unaffected by leaks (sometimes experienced with hollow

floats) or absorption. While the final fuel filter adjustment is

made with the carburetor installed on the engine, a bench

adjustment can be made before installing bowl as follows:

a. Loosen lock screw enough to allow adjusting nut to be

turned.

b. With fuel bowl inverted turn adjusting nut until float lever is

parallel with floor of bowl (Fig. 48). Tighten lock screw.

13. Install fuel bowl screw gaskets on fuel bowl screws. This

will prevent threads from shaving off gasket particles into fuel

bowl.

14. Position metering body gasket (see Fig. 49) on the

dowels on the back of the metering body. Assemble metering

body on main body and fuel bowl on metering body. Insert

four fuel bowl screws and tighten to 25-30 inch pounds.

15. When positioning fuel bowl the accelerating pump lever

must be slightly depressed to clear the diaphragm pump

lever. When spring loaded bowl screws are used the following

procedure should be used:

Tighten each spring loaded bowl screw by rotating screw head

until screw assembly bottoms in main body.

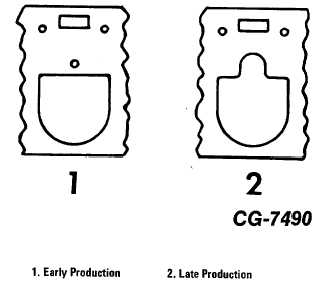

Figure 49 Both Metering Body Gaskets are Furnished in

Carburetor Rebuild Kits

Bottoming of screw assembly is accomplished when screw

head "springs back" about one quarter (¼ ) turn when screw

driver is removed from slot. Excessive rotation of screw head

can destroy spring.

16. Apply Vaseline to the fuel transfer tube "O" ring seals and

place the seals against the flanges on both ends of the fuel

transfer tube and install one end of the tube in the primary fuel

bowl.

Secondary Fuel Bowl and Metering Block:

17. Assemble the secondary fuel bowl by following Steps 9

through 12. As a preliminary secondary float adjustment,

adjust the float so that the top of the float is parallel to the

bowl floor with the bowl in an inverted position (Fig. 48).

18. Install the following parts in the secondary metering

block.

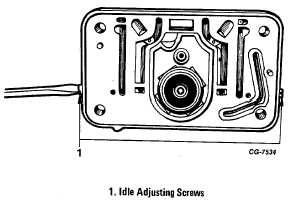

Figure 50 Secondary Metering Block

CGES-125-T Page 32

PRINTED IN UNITED STATES OF AMERICA

|