|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

To obtain proper bearing assembly with the correct

"crunch," care must be taken when tightening the clamping

bolts and nuts to make sure they are drawn down alternately

and evenly using a tension wrench and tightened as specified.

Rod caps or blocks must not be filed, lapped or

reworked in any other manner in order to reduce clearance.

While such practice may make a tighter fit at top and bottom,

it will result in an out-of-round bore and bearing shell

distortion.

Main and connecting rod bearings are designed with

the "spread" (width across the open ends) slightly larger than

the diameter of the crankcase bore or connecting rod bore into

which they are assembled. For example, the width across the

rod bearing not in place is approximately .025" more than

when the bearing is in position. This condition is designed

into the bearing to cause it to spread outward at the parting

line when "crush" load is applied by tightening the nuts and

bolts. Some of this "snap" may be lost in normal use, but the

bearing need not be replaced because of a nominal loss of

this condition.

This condition causes the bearing to fit snugly in the

respective bore. The bearing must be "snapped" or lightly

forced into its seat, Figure 125.

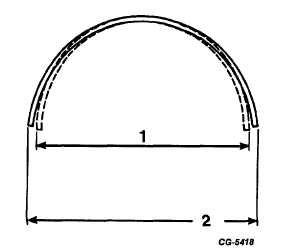

Fig. 125 Illustrating Bearing Spread

1.

O.D. of bearing

2.

Spread of bearing

when installed

before installation

is the same as the

diameter of the

crankshaft or conn.

rod bore.

BEARING SPREAD DIMENSIONS

Bearing O.D.

Specified

Spread of

(Installed)

Spread

Bearing "A"

Fig. 122

Connecting Rod Bearings

2.6245-2.6250

.030-.0305

2.6545-2.6555

Main Bearings

No's 1, 2, 4 & 5

3.3160-3.3152

.0200-.0208

3.336

No. 3 (Thrust)

3.3160-3.3152

.0020-.0168

3.318-3.332

B. Fitting Main Bearings

To obtain an accurate reading using the Plastigage

method of checking, all bearing caps must be in place and

torqued to specifications.

1.

Remove one bearing cap and insert. Remaining caps

are left tight while checking the fit of this bearing.

2.

Wipe the oil from all contact surfaces such as

crankshaft journal, bearing insert, bearing caps, etc.

3.

Place a piece of Plastigage the full width of the

bearing surface on the crankshaft journal (or bearing

cap insert) approximately ¼ " off center. Install

bearing cap and tighten cap bolt to recommended

torque.

NOTE: Do not turn crankshaft while making

check with Plastigage.

4.

Remove bearing cap and insert.

5.

Do not disturb Plastigage. Using the Plastigage

envelope, measure the widest point of the Plastigage,

Figure 126. This reading indicates the bearing

clearance in thousandths of an inch.

6.

If the bearing clearance is not within specifications,

the crankshaft must be reground and underside

bearings installed.

CGES-210 Page 50

PRINTED IN UNITED STATES OF AMERICA

|