|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

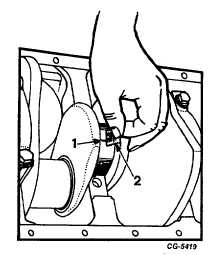

Fig. 126 Checking Main Bearing Clearance

1. Plastigage flattened

2. Gauge

7.

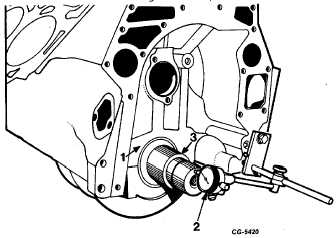

The third crankshaft bearing controls the crankshaft

thrust and provides initial location of the crankshaft

in relation to the crankcase. Use dial indicator to

check end play, Figure 127.

C. Fitting Connecting Rod Bearings

1

Remove bearing cap and wipe oil from face of

bearing insert-and exposed portion of crankshaft

journal.

2.

Place a piece of Plastigage on the bearing surface

the full width of the bearing about ¼ " off center.

Fig. 127 Checking Crankshaft End Play

1.

Crankcase

3.

Crankshaft

2.

Dial indicator

3.

Install cap and tighten to recommended torque.

NOTE: Do not turn crankshaft while Plastigage is in

place.

4.

Remove bearing cap and use Plastigage scale to

measure widest point of Plastigage, Figure 128. This

reading

indicates

the

bearing

clearance

in

thousandths of an inch.

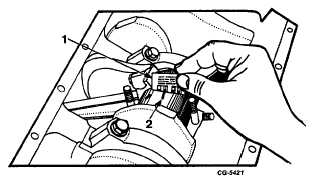

Fig. 128 Checking Connecting Rod Bearing Clearance

1. Gauge

2. Plastigage flattened

5.

If the bearing clearance is not within specifications,

the crankshaft must be reground and undersize

bearings installed.

6.

Check the connecting rod end clearance using a

feeler gauge as shown in Figure 129. Excessive

clearance may require replacement of rods or shaft.

The check should be made to make certain the

specified running clearance exists. Lack of clearance

could indicate a damaged rod or a rod bearing out of

position.

CGES-210 Page 51

PRINTED IN UNITED STATES OF AMERICA

|