|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

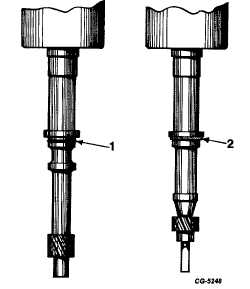

Fig. 7

1.

"O" Ring

2.

Gasket

DISTRIBUTOR SHAFT AND BUSHING WEAR TEST

This procedure can be used to check condition of the

distributor shaft and shaft bushings in the distributor housing.

1.

Clamp distributor in a vise equipped with soft jaws and

apply only enough pressure to restrict movement of

distributor.

2.

Remove distributor rotor and dielectric shield (dust

cover).

3.

Attach dial indicator to distributor housing so that

indicator plunger rests against top portion of trigger

wheel assembly (Figure 8). C20

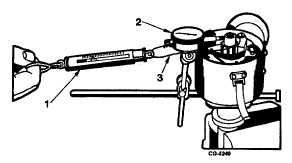

Fig. 8 Shaft and Bushing Wear Test (Checking Distributor

Shaft Side Play)

1. Spring Scale

2. Dial Indicator

3. Wire Loop

4.

Place one end of a wire loop around top of trigger

wheel assembly (rotor shaft). Hook a spring scale in

other end of wire loop and pull on a line with plunger of

dial indicator (Figure 8). Wire loop must be

perpendicular to shaft to assure a a straight pull.

Also, loop must not interfere with dial indicator

mounting bracket.

5.

Apply one-half (½ ) pound of pull on spring scale and

read movement of plunger on indicator dial. Apply

one-half (½ ) pound of pull in opposite direction and

again read movement on indicator. Peak-to-peak side

play is the sum of these two readings.

If distributor shaft side play exceeds maximum

permissible

limit

(see

DISTRIBUTOR

TEST

SPECIFICATIONS), replace distributor shaft bushings

(see Distributor Housing Bushing Replacement).

DISTRIBUTOR OPERATION TEST

(On Test Stand)

Operation of the distributor can be checked on a

distributor test stand.

It is advisable to perform the distributor operation test

prior to disassembly of the distributor for service. This test will

give valuable information about the condition of the distributor

and indicate where parts replacement may be required.

Preparation of Distributor Test Stand

(Refer to Figure 9)

Additional equipment required:

Battery, 12 volt (fully charged).

Jumper Wires (2) with clips at each end.

1.

Mount distributor to be tested in test stand.

2.

Clip test stand distributor lead to ring connector on

brown distributor lead.

3.

Clip test stand ground lead to ground stud on

distributor mounting frame.

CGES-145-U Page 6

PRINTED IN UNITED STATES OF AMERICA

|