|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

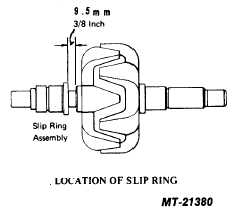

There is no stop on the shaft to prevent the slip rings

from being pressed on too far. It is therefore necessary

to press the slip rings only to a point where there is 9.5

mm (3/8") space between the inner edge of the slip rings

and the rotor (see Fig. 25).

REASSEMBLY

1. If slip ring end bearing has been removed, press a new

bearing in place from the outside of the housing. Bearing

should be installed with seal facing in toward slip rings.

When properly installed, the manufacturer's part number

stamped on the end of the bearing will be facing toward

the outside of the housing.

Bearing should seat against lip on inside end of bearing bore.

After bearing is installed, apply a small amount of grease

(Chevron SRI 2 or equivalent) to rollers.

2. Reinstall heat sinks in slip ring end housing. Be sure that

upper and lower insulating washers are in their proper

location. Install but do not tighten lower heat sink retaining

screws,

lockwashers,

guardwashers

and

insulating

washers (see Fig. 9).

Replacement heat sinks may differ in thickness or appearance

from the original assemblies, but will fit and function

interchangeably.

3. Install terminal bolts and regulator lead wires. Red wire

goes on positive heat sink and black wire goes on

negative. Be sure that mating surfaces of heat sinks,

terminals and terminal bolts are clean and free of paint to

insure a good electrical connection (see Fig. 7).

4. Install two insulating bushings on each terminal bolt and

install regulator housing.

5. Be sure that red and black regulator leads are properly

routed through cutaway section of end housing, and

install and tighten nuts on terminal bolts (see Fig. 4).

5. Tighten lower heat sink screws and check all leads for

proper routing, being sure that no lead is pinched under

heat sink.

6. Reinstall capacitor.

7. Reinstall stator and terminal nuts. It is advisable to align

stator and housing by temporarily installing the through

bolts.

8. Press drive end bearing into housing and reinstall bearing

retainer and four screws.

When installing bearing, press on outer race to avoid

transmitting force through the bearing balls which could

brinnell the bearing.

9. Press drive end housing and bearing onto rotor shaft.

Using a sleeve around the shaft, press on the inner race

to avoid brinnelling the bearing.

10. Install rotor and housing assembly into stator and slip

ring end housing assembly, being sure that mounting

ears are aligned.

11. Install three through bolts and self locking nuts. Torque

to 5.6-6.8 N.m (50-60 in. lbs.). Place a small amount of

grease (Chevron SRI 2 or equivalent) in housing and

reinstall the metal dust cap by carefully pressing it into

place.

12. Install diode trio and three nuts.

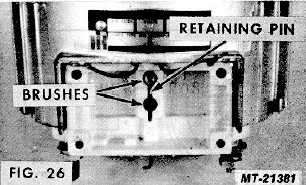

13. Insert outer brush and spring assembly into the housing

and compress the brush spring, using a small

screwdriver or similar tool. While holding the spring

compressed, insert

PRINTED IN UNITED STATES OF AMERICA

Fig. 25

CTS-2743T Page 11

|