|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

a pin through the hole in the rear of the housing so that

the spring will be held in a compressed position. (A

suitable pin can be made from a piece of 1.6 mm (1/16")

drill rod). Install and compress the remaining brush and

spring assembly in a similar manner. Hold the spring in a

compressed position by pushing the pin farther into the

housing (see Fig. 26).

14. Attach red and black leads to regulator. Attach blue

regulator lead to diode terminal screw by placing the

spade terminal under the head of the screw. Tighten nut

on terminal screw (see Fig. 4). Install regulator.

Be sure that the red and black leads are properly routed

through their slots in the regulator housing. Install four

regulator screws. Withdraw brush retaining pin before

tightening these screws.

15. Install diode trio lead and nut.

16. Install spacer, key, fan, pulley and nut. Torque nut to 95-

108 N.m (70-80 ft. lbs.). Due to the design of the

alternator, a certain amount of shaft end play will be

present in new or rebuilt units. This end play is designed

into the unit and will vary between 0.1 to 0.3 mm (.004 to

.012 inch).

CAUTION

DO NOT FORCE OR POUND PULLEY ON

SHAFT.

TESTING

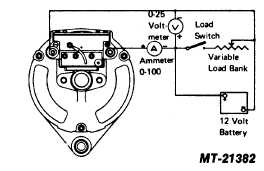

Because of the integral regulator used on this

alternator, the test block hookup is very simple, consisting of

connecting the positive and negative output leads. If a

commercial test block is not available, the test setup shown in

Figure 27 may be used.

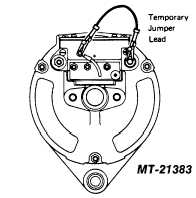

Before beginning the test and after the battery has

been connected, momentarily flash the field by connecting a

jumper between the diode trio terminal and the alternator

positive output terminal (see Fig. 28). This will restore the

residual magnetism which may have been weakened by

handling or repair procedures.

VOLTAGE REGULATOR REPLACEMENT

REMOVAL

1. Remove four screws and carefully lift regulator free of

housing. Remove red and black leads from regulator

noting their position to facilitate assembly of new

regulator (see Fig. 4).

2. Remove lead from diode trio to terminal regulator housing.

Loosen inner nut which will allow blue regulator lead to be

withdrawn from under head of terminal screw. Remove

regulator (see Fig. 4).

3. Lift brush and spring assemblies out of housing (see Fig.

4).

INSTALLATION

1. Install brushes.

When brush springs have been compressed, hold them in

place by passing a pin through the retainer hole (see Fig.

26). A suitable pin can be made from a piece of 1.6 mm

(1/16") drill rod.

2. Attach red and black leads to regulator with shake-proof

spring lockwashers and nuts supplied. Attach blue

regulator lead to diode terminal screw by placing the

space terminal under the head of the screw. Tighten nut

on terminal screw (see Fig. 4). Install regulator.

Continued on Page 14

FIG. 27

FIG. 28

CTS-2743T Page 12

|