|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BODIES AND CABS

6.

After clamping fender to hood on D-400 series check

position of lower corner of inside rear reinforcement

channel. In some cases, the rear reinforcement

channel corner will not line up with inside hood

channel. See Fig. 10. This is due to slight variations

of hoods. To position correctly, cut off reinforcement

for reinstallation after fender has been attached.

7.

Drill holes from inside of hood through fender flanges

for installation of No. 10 sheet metal screws to hold

fender in place. Holes should be spaced 3 to 4" apart.

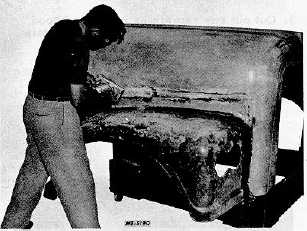

Observe fender alignment to hood. See Fig. 11.

Fig. 11 Service Fender Mounting.

8.

Grind or buff all joining edges and radius to normal

thickness on cowl contours. Blow off all surfaces and

corners. Clean with acetone on a soft cloth.

9.

Cut several four inch strips of mat material (2" each

side of seam). Then on a piece of polyethylene

position two layers of mat saturated with the resin

mixture. Apply resin mixture to the inside of hood

where material is being repaired. When tacky, position

the strips (2 layers) over seam. Use the polyethylene

to press out air bubbles. Allow to cure.. Additional

coats of the resin mixture may be applied to the area if

desired. NOTE: If holes are left where the new fender

may not cover the damaged area, repair these places

as outlined in instruction for repairing holes.

10.

Refer to item 6. If required, remount inside rear

channel

reinforcement

corner.

Grind

edges

and

mounting surfaces for proper bonding. Apply saturated

sections

of mat to all edges and seam to hood channel. If

corner positions correctly as applied on fender, apply

mat required to joining seam only. Brush out air

bubbles with a squeegee.

11.

Before proceeding on outside repairs, allow inside

sections to harden. To speed drying or curing time,

apply heat with lamps. No further inside refinishing is

required. Surfaces may be undersealed.

12.

Grind off outside screw threads holding fender in place

just below seam surface. Take grinder or sander and

dish out concave strip approximately one inch wide

along hood and fender seams.

13.

Apply one four inch strip of mat saturated with the resin

along concave hood and fender seams. Next apply a

four inch strip of cloth saturated with the resin mixture

to the fender seams for additional strength. Use a

squeegee or polyethylene sheet to force out entrapped

air. Allow time for assembly to cure. Trim off any mat

overhang at edges.

14.

Grind or sand all outside hood and fender joined

laminated seams. See Fig. 12

Fig. 12 Service Fender and Hood Refinishing.

15.

With plastic putty fill any existing low spots or surface

cracks with plastic putty. 16. Sand the entire exterior

smooth, using a #400 grit paper. See Fig. 12. Clean

surface with acetone or lacquer thinner. Apply prime

coat and follow with standard automotive refinishing

procedures. See Fig. 13.

CTS-2408 Page 6

PRINTED IN UNITED STATES OF AMERICA

|