|

| |

TM5-4210-229-14&P

6-18.

TRANSFER CASE REPAIR (Continued).

h.

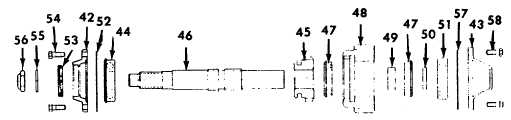

Front output shaft removal.

(1) Remove the seal carrier (42) from the front of the

case and the cap (43) from the rear of the case.

Drive the shaft from the rear of the case until the

front bearing (44) is clear of the housing. Use a

bearing puller between the bearing and the case

to remove the bearing from the shaft. The shaft

and gear assembly can now be removed.

(2) Remove the shaft from the gear in an

arbor press.

REPAIR

a.

Parts cleaning.

Cleaning solvent (Appendix D, Item 54) is

both toxic and flammable. Keep off skin. Use

only in a well ventilated are and avoid

prolonged breathing of vapors. Keep away

from open flames.

(1) Clean all components with solvent (Appendix D,

Item 54).

Compressed air used for cleaning or drying

can create airborne particles that may enter

the eyes. Pressure shall not exceed 30 psi

(206 kPa). Wearing of goggles is required to

avoid injury to personnel.

(2) Dry all parts after cleaning with a clean, soft shop

towel (Appendix D, Item 55). Compressed air

can be used to dry in accessible areas of large

parts. Compressed air should not be used to spin

dry bearings. Spin dry-ing bearings may cause

damage to the mat-ing surfaces due to lack of

lubrication.

(3) To prevent corrosion damage, dried parts

should be immediately coated with a light oil

(Appendix D, Item 37).

b.

Inspection.

(1) Carefully inspect all parts being reused for signs

of wear or damage. Examine all bearing

surfaces, ball bearing assemblies and roller

bearing cups and cones for wear, pitting or

overheating. Examine gears for pitting, scoring

and broken teeth. Shafts should be examined

for nicks, mars, and damaged threads. Check

all shift forks and slots in sliding clutches for

extreme wear or discoloration from heat. Also

check the teeth engagement of the sliding

clutches

for

partial

engagement

pattern.

Discrepant parts or any part showing signs of

wear or damages should be repaired or replaced.

ASSEMBLY

NOTE

All parts must be clean and all gasket surfaces

must be free of old gasket material.

In order to reduce chances of galling or

scoring and to provide initial lubrication for

the oil seals, lubricate housing bores, shaft

splines and-bearing mounting surfaces, and

sealing lips on oil seals with Lubriplate

(Appendix D, Item 34)or equal.

When installing bearings, use flanged end

bearing drivers that will apply equal force to

both inner and outer races of the bearings. If

tubular or sleeve type drivers are used,

apply the force to either the inner or outer

race or both races as needed to put the

bearing in place without pushing through the

bearing balls.

6-98

|