|

| |

TM5-4210-229-14&P

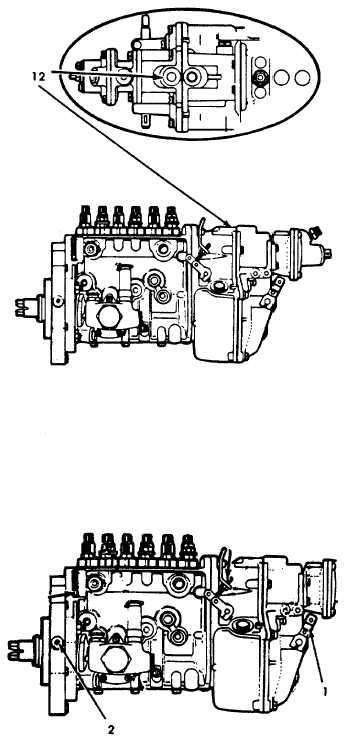

4-76. FUEL INJECTION PUMP REPLACEMENT (Continued).

k.

Install fuel supply, fuel return and high pressure

injection lines with all clamps and brackets. Clean

inside of each injection line with filtered air before

assembling to injection pump and nozzles. Torque

line nuts to 30 ft-lb (41 N.m).

l.

Remove all protective caps and install and connect

all other applicable lines, hoses and wires to the

pump.

m. Add minimum of one pint of engine oil to governor

through the upper governor housing plug (12). Be-

cause injection plug is splash lubricated, engine oil

must be added to a replacement pump.

n.

Install throttle cable or linkage to outer control

lever (1). Adjust throttle cable or linkage so tang in

outer control lever is in override position. At over-

ride lever tang will be approximately half way from

center of control lever to end of slot.

o.

After installation of fuel injection pump, prime fuel

system using these procedures.

(1) Loosen all six high pressure fuel lines at nozzle

end.

(2) Loosen hand priming pump handle.

(3) Operate priming pump until pump action be-

comes solid (harder to pump).

(4) Position injection pump shutoff lever in run

position with electric shutoff or mechanical ca-

ble.

(5) Crank engine for fifteen seconds.

(6) Operate priming pump until pump action be-

comes solid. Tighten priming pump handle se-

curely.

(7) Crank engine for fifteen seconds and observe

fuel/air leakage at each nozzle/fuel pipe con-

nector. When fuel flows from each nozzle con-

nector, tighten connector.

(8) Start engine and operate until engine runs

smoothly.

4-90

|