|

| |

TM5-4210-229-14&P

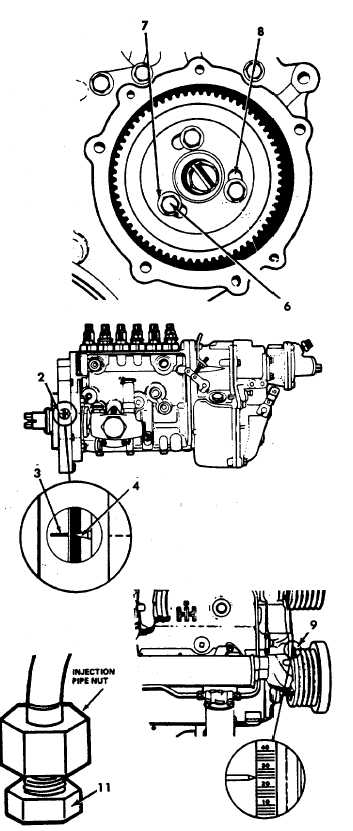

4-76. FUEL INJECTION PUMP REPLACEMENT (Continued).

j.

Remove injection pump drive gear bolts (6) and

washers (7) from injection pump hub and remove

pump from engine.

INSTALLATION

a.

Install injection pump drive gear loosely to injection

pump using drive gear bolts (5) and washers (7).

b.

Rotate pump clockwise (as viewed from drive gear

end) until timing mark (3) on pump drive hub is

aligned with timing pointer (4) in adapter hole (2).

c.

Rotate loosened pump drive gear counterclockwise

(as viewed from drive gear end) to 3/4 of full extent

of drive gear bolt slots (8).

d.

Install final filter to injection pump hose and rubber

coated clamp. If the clamp is omitted, the hose

may rub on adjacent parts and leak.

e.

Install final filter to pump housing hose to inlet

connector on pump housing.

f.

Clean front cover plate and install new gasket and

injection pump assembly.

g.

With injection pump in position on engine, secure

pump adapter to front plate with bolts, nuts, and

washers. Torque bolts and nuts to 24 ft-lb (33

N.m).

h.

Verify alignment of pump timing pointer (4) to hub

mark (3) through mounting adapter opening (2).

Rotate pump drive hub as required for proper

alignment. Torque pump drive gear bolts to 35 ft-lb

(47 N.m). Observe engine to injection pump timing

on pulley (9).

i.

Install drive gear access cover (10) with applicable

capscrews and washers (5).

j.

Install lubricating oil line to injection pump.

CAUTION

Injection pump delivery valve holder (11)

must be held with a wrench to prevent

movement when high pressure piping is

being installed.

4-89

|