|

| |

TM 5-4210-220-34

3-7.

TRANSMISSION-Continued

(12)

Before installing the seal ring, the end clearance must be checked to ensure that the seal ring has not

been expanded.

(13)

Remove the seal ring from its sealed package. Place it in its operational position Inside the bore that it will

be sealing.

(14)

Using a feeler gage, check the end clearance of the seal ring. The end clearance must not be less than

0.010 in. (0.25 mm).

(15)

If the end clearance is less than 0.10 in. (0.25 mm), bake the seal ring in an oven at 200-300 deg. F (93-

149 deg. C) for 24 hours or get a new seal ring. Recheck end clearance.

(16)

Pack the seal ring and its groove with a liberal amount of petroleum jelly (item 21, Appendix B).

(17)

Roll up the seal ring to about half its free diameter and hold it that way for about 10 seconds. Being

careful not to spread the seal ring more than necessary, slide it onto the hub. Place one end of the

seal ring into the groove and gradually

work the seal into the groove.

(18)

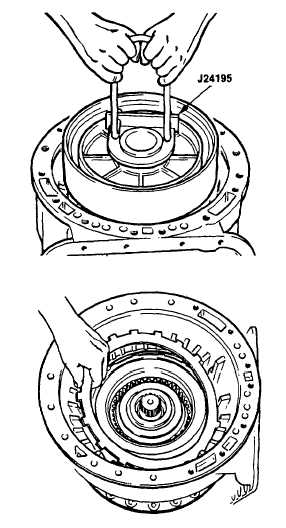

Attach lifting bracket J24195 and install

the center support assembly. Aline the

tapped hole in the support to the hole in

the transmission housing.

(19)

Install the special 3/8-16 X 3 in. bolt and

plain washer, fingertight. Remove the

lifting bracket.

NOTE

It may be necessary to compress the center

support to install the selective snap ring.

(20)

Install the selective snap ring that retains

the center support. Be sure the gap of

the snap ring is at the top of the

transmission housing.

am.

Installation Third And Fourth Clutch

(1)

When installing the third clutch plates,

the external-tanged clutch plates must

have a definite tang-to-slot relation. The

tangs must be installed into the shorter,

narrower slots.

(2)

Install ten third-clutch plates, beginning

with a thick external-tanged plate and

alternately installing five external-tanged

plates and five internal-splined plates.

3-76

|