|

| |

TM 5-4210-220-12

4-25. STEERING SYSTEM - Continued

4-25.6 Power Steering Gear - Continued

b.

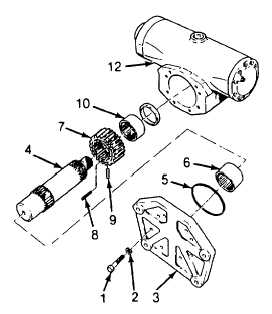

Output Shaft Repair - Continued

(7)

Remove quad ring (11) and discard.

(8)

Remove roll pin (8) and drill out pin (9).

Press gear (7) off shaft (4).

NOTE

If pin (9) cannot be drilled out, it

can be sheared off using a press

capable of providing approximately

10 tons of pressure. After pin is

sheared and gear and shaft are

taken apart, drill remaining pin

half out of shaft and drive other

half out of gear.

(9)

Clean inside of gear housing using a

clean, dry, lint-free cloth. Do not use

liquid cleaning agents.

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard's solvent) is potentially dangerous. Avoid

repeated and prolonged breathing of vapors and skin contact with the liquid. Do not use near

open flame, arcing equipment or other ignition sources. Always wear eye protection and

protective clothing. The flash point of P-D-680 is 100 to 138 deg. F (30 to 59 deg. C).

Death or serious injury could occur if compressed air is directed against the skin. Do not use

compressed air for cleaning or drying unless the pressure is/has been reduced to 30 psi (2.11

kg/cm2) or less. When working with compressed air, always use chip guards, eye protection,

and other personal protective equipment.

(10)

Clean all reuseable parts removed from steering gear using cleaning solvent (item 10, Appendix E) and

blow dry using compressed air.

(11)

Inspect shaft (4) and pinion gear (7). Replace either part if damaged.

(12)

Coat new and reuseable parts with lubricating oil (item 17, Appendix E) in preparation for assembly.

(13)

Press new bearings (6 and 10) in place in cover (3) and housing (12). Be sure bearings are flush with

internal cover and housing surface (faces toward pinion gear).

(14)

Install new quad ring (11) in groove in housing (12). The ring may appear to be too large but will fit.

(15)

Aline timing arrow on output shaft (4) with arrow on pinion gear (7) and press gear onto shaft.

(16)

Install retaining pin (9) and secure it using roll pin (8).

4-492

|