|

| |

TM 5-4210-220-12

4-25 STEERING SYSTEM - Continued

WARNING

The pitman arm can work loose

and result in loss of vehicle

steering control unless the arm is

installed and secured as detailed

in steps 5 thru 8.

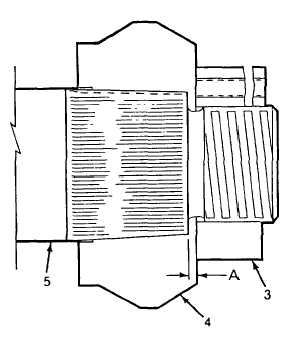

(5)

Install and tighten nut (3) to approximately

450 ft lb (610 Nm).

(6)

Remove nut (3). Measure distance A

between pitman arm and shaft shoulder

as shown. Distance A should be 1/8 to

3/32 in. (3 to 4 mm). If less than 1/8 in. (3

mm), replace output shaft as detailed in b.

following.

(7)

Install nut (3) and tighten to 675 ft lb (915

Nm).

(8)

Install lockwasher (2) and capscrew (1).

Tighten capscrew to 15 ft lb (20 Nm).

b.

Output Shaft Repair.

NOTE

Steering gear removed from truck.

WARNING

To prevent a serious accident, do

not weld or apply excessive heat

to pitman arm or output shaft.

Welding or excessive heat may

lead to component failure and

loss of steering control.

(1)

Remove pitman arm as detailed in a

preceding.

(2)

Remove screws (1) and washers (2)

attaching cover (3).

(3)

Using a soft hammer, tap on end of output shaft to loosen cover.

(4)

Carefully slide output shaft, pinion gear, and cover through housing. Pull output shaft (4) out of cover (3)

and discard O-ring (5).

(5)

Inspect bearings (6 and 10) while these are still installed in gear housing (12) and cover (3). The bearings

should remain installed unless damaged or defective.

(6)

If replacement of either bearing is required, use a suitable internal bearing puller to remove the defective

bearing.

4-491

|