|

| |

TM 5-4210-220-12

4-15. AUXILIARY POWER UNIT - Continued

4-15.8 Engine Intake and Exhaust Valves - Continued

(9)

Inspect valve guides. If guides are excessively

worn (see table), are grooved or have carbon

deposits, replace valve guide. (See REPAIR

following).

(10)

Inspect valve seats if badly scored or they have

an irregular wear pattern resurface seat. If seat

diameter is greater than 1.06 in. (27 mm)

(intake) 0.91 in. (23 mm) (exhaust) replace seat.

See REPAIR following.

(11)

Lap valves and seats with valve grinding

compound (item 31, Appendix E) even if neither

is replaced.

(12)

Inspect valve springs. Replace if broken,

cracked or chipped. Check free length equals

1.65 in. (42 mm).. With load of 51 lb (23 kg)

spring length must be 1.26 in. (32 mm).

Replace

if

spring

will

not

meet

these

specifications.

INSTALLATION

(1)

Install valves in cylinder head.

(2)

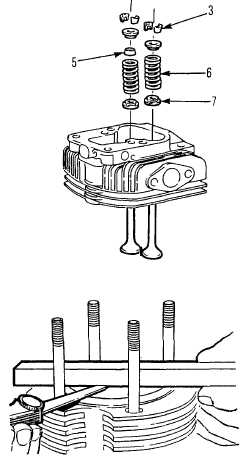

Install valve spring retainers (7) valve springs

(6) valve seal (5, intake only), upper retainer

over valve shafts.

(3)

Compress each spring in turn and install spring

retainer (3) over valve shaft.

(4)

Install injector into cylinder head, see para. 4-

15.7 INSTALLATION.

(5)

Replace push rod cover upper and lower seals

on cover. Install cover in engine block.

(6)

Rotate flywheel until piston is at top dead

center. Measure piston crown face to cylinder

edge clearance.

(7)

Crown face of piston must be between 0.008 in.

(0.20 mm) higher and 0.006 in. (0.15 mm) lower

than cylinder edge.

(8)

Adjust clearance by selecting one of the

following cylinder head gaskets.

4-164

|