|

| |

TM 9-254

4-1.

Torque Wrench - Continued

(2)

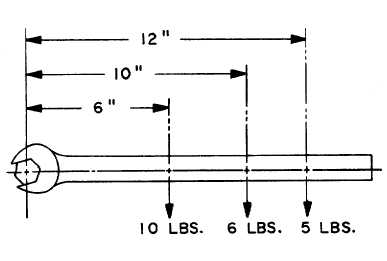

Since it is known that distance times force will give us the torque of a given application it is a simple

matter to turn the formula around and build a tool for a known torque requirement (fig. 4-2). Using the

same example and knowing only the torque requirements of a tool: 60 inch-pounds = L x F

Figure 4-2. Length vs Force - Torque

(3)

We know that the tool can have a leverage of 10 inches with a 6 pound pull, 12 inches with a 5 pound

pull, or even 6 inches with a 10 pound pull. The tool can be built to fit the application whether a long or

short lever is required, a curved lever to fit a hard-to-reach fastener, a self-contained tool or one that will

take many adapters or accessories.

c.

Use of a Torque Wrench (fig. 4-3). A torque wrench must be used when manuals call out torque on a nut or

bolt.

CAUTION

Do not use a torque wrench to loosen nuts or bolts. This will damage the wrench.

(1)

Threads should be clean, free of burrs, and lubricated before torquing. Use a little light lubricating oil or

anti-seize compound.

NOTE

Use a wrench to make sure bolt or nut is snug. Then use the torque wrench.

(2)

When torquing, the hand should be in center of handle (1) as shown and not too far in (2), or too far out

(3).

4-2

|