|

| |

TM 9-254

3-7.

Worm and Worm Gear Mechanisms - Continued

b.

Maintenance of Wormshaft. For a wormshaft to operate properly, the shaft itself must be absolutely true and

straight, to prevent the worm from being thrown off center at each revolution of the shaft and causing a binding movement

in the worm and worm gear mechanism. If such binding occurs, it is frequently due to a bend or, more often, several

bends in the shaft. In such cases, the entire wormshaft should be replaced. It may sometimes be necessary to locate and

straighten these bends. This process involves much skill and the ability to select from a wide variety of methods best

suited to the particular condition found. No specific procedure can be outlined. Generally, the entire length of the shaft

must be continually tested during the straightening process and the shaft must be straightened to a point where the worm

thread will be no more than 0.001 inch off center when the shaft is rotated in its bearings. Care must be taken to avoid

damaging the worm thread or any of the bearing surfaces while straightening the wormshaft.

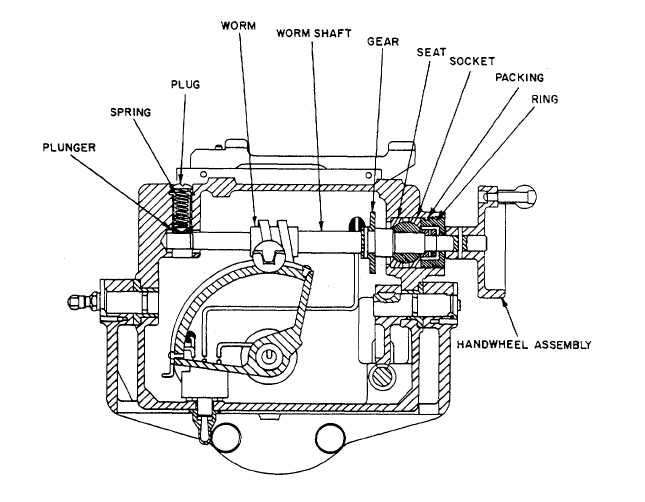

Figure 3-15. Typical Worm and Worm Gear Mechanism

c.

Maintenance of Wormshaft Ball. The wormshaft ball plays an important part in obtaining a smooth

nonbinding movement free from backlash therefore, the ball must be perfectly round. An out-of-round ball provides a poor

bearing surface and will cause binding in the throwout mechanism, as well as being a source of backlash trouble.

3-13

|