|

| |

TM 9-254

3-6.

Swaging - Continued

Section III. MECHANICAL ASSEMBLIES

3-7.

Worm and Worm Gear Mechanisms.

a.

General. The worm and worm gear principle is widely used in fire control instruments as a means of rotating

an instrument in azimuth and in elevation. This principle has been adopted as the standard for mechanical movements in

almost all rotating instruments.

(1)

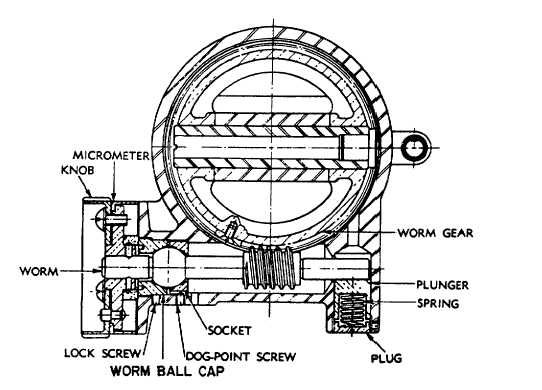

Figure 3-14 illustrates a worm and worm gear mechanism using a worm ball cap, which is threaded for

adjustment to prevent lateral movement of the worm. The worm is held in mesh by a spring and plunger

arrangement on the end.

CAUTION

Worm ball caps presently in use in some instruments, are made of brass, phenolic (plastic), or

nylon. Any attempt to lap ball caps make of phenolic, or nylon will damage these items.

Figure 3-14. Worm and Worm Gear Mechanism Using the Worm Ball Cap

(2)

Figure 3-15 illustrates a typical worm and worm gear mechanism using a seat, socket, and threaded ring

to prevent lateral movement of the worm. The thread ring is used for adjustment and the worm is held

in mesh by a spring and plunger arrangement on the one end. Before proceeding with any maintenance

work in connection with this type of mechanism, all maintenance work for the wormshaft, as outlined in b

below, must be thoroughly understood.

3-12

|