|

| |

TM 9-254

3-6.

Swaging - Continued

c.

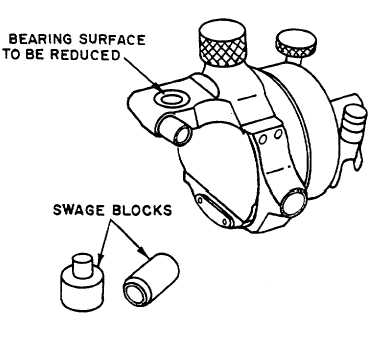

Example of Typical Swaging Job. For example, suppose that, in the aiming circle M1, the bearing surface for

the right trunnion of the telescope has become worn, resulting in a loose fit. To overcome this condition, a pair of swage

blocks must be made which will assist in reducing the size of the hole. The analysis of this particular condition is illustrated

in figures 3-11, 3-12, and 3-13. The important feature of these swage blocks is the diameter of the pilot on the lower block

that must fit the bearing surface. It must be of exactly the same diameter as the right trunnion of the telescope. As the

blows are struck on the blocks, turn the body of the aiming circle around at different points so that an even pressure on the

metal will be obtained. This particular job will not require many blows since the material is brass and very thin. If the

material was heavier and difficulty was encountered in reducing the size of the hole, the upper block could have a raised

portion, as illustrated in figure 3-13. The raised portion tends to localize the blows and increase the flow of the metal. A

block of this type may be used only when the surface contacted does not have to be flat.

Figure 3-11. Swage Blocks Prepared for Use

d.

Precautions. When properly practiced, swaging will move the metal throughout its entire thickness. If the

blows are struck lightly, only the surface of the metal will move and the piece will soon return to its undesired shape.

Therefore, make sure that the metal is moved throughout its entire thickness. After the blocks have been used, they

should be cleaned, a light coat of oil applied to them, and then they should be stored in a dry place.

3-10

|