|

| |

TM 9-254

3-5.

Peening - Continued

b.

Preparation for Peening. Most of the preparation for a peening job consists of an analysis of where to do the

striking. The spherical indentations caused by the use of a ball peen hammer cause the metal to spread. Thus, the

selection of the proper tool is an important factor in preparation. The part to be peened must always be backed up with the

proper tool or holding device

c.

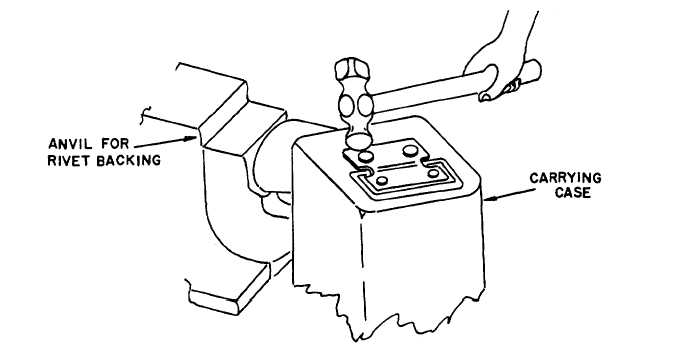

Procedure. For example, suppose that the handle of a carrying case has become loose. It is decided to

tighten this handle by peening the rivets which secure it to the case. Figure 3-10 illustrates the use of an anvil placed on

the under side of the handle to back up the rivets, and the blows being struck on a rivet with the peen of the hammer. The

blows must be so directed as to cause the metal of the rivet to flow, tightening the assembly, the blows should be light and

the metal must flow slowly and smoothly.

Figure 3-10. Peening a Rivet

3-6.

Swaging.

a.

General. Swaging is a process used to move metal when a series of hammer blows (peening) is difficult to

control or where a smooth resulting surface is required. Swaging is performed by successive blows on dies, called swage

blocks, which are shaped in such a manner as to give a required form. For instance, if a flat square form is desired, the

swage blocks would be two pieces of flat stock. Curved forms will require curved blocks

b.

Preparation for Swaging. Much of the preparation is in the analysis of the job, as in peening. The principal

question is where to exert the force to do the most good. Selecting the swage blocks is also primarily important. In some

cases these blocks will require machining to accurately meet a required dimension.

3-9

|