|

| |

TM 9-254

4-22.

Files - Continued

(3)

When filing hard metals, apply pressure on the forward stroke only. The file should be lifted from the

work on the return stroke to prevent the teeth from becoming dull. When filing soft metals, pressure on

the forward and return stroke will help keep the cuts in the file clean of waste metal and will not dull the

teeth.

(4)

Use a rocking motion when filing round surfaces.

(

(5)

When using a new file, too much pressure or force may cause the teeth to break off. File slowly, lightly,

and steadily. Too much speed and too much pressure causes the file to rock and will round off the

corners of the work.

4-23.

Removing Nicks and Burrs.

a.

General. Burrs are thin edges or rough spots left on metal surfaces and are common on outside and inside

screw threads. Nicks are small grooves or cuts in the metal surface and can form either ridges, uneven surfaces or burrs.

b.

Nick and Burr Removal. The following are suggested ways of removing nicks and burrs:

(1)

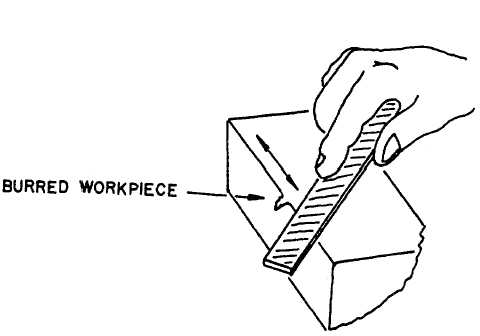

To remove burrs from straight edge, hold a flat file at an angle to the edge as shown in figure 4-49, and

move the file back and forth along the edge until the edge is smooth and even.

Figure 4-49. Using a Flat File.

4-54

|