|

| |

TM 9-254

4-2.

Use of Gages - Continued

(2)

The following is a recommended procedure for obtaining a correct reading when using a thickness gage.

(a)

Estimate the thickness needed to fill the space being measured.

(b)

Choose several thicknesses of blades to fill the space being measured.

(c)

Turn the blades so that they are stacked together and try to insert stacked blades into space being

measured.

CAUTION

Do not force blades into space at any time. Forcing blades may damage either the blades

themselves or the surfaces of material being measured.

(d)

If stacked blades are too thick to fit into space, fold back thick blades one at a time and substitute

thin blades in place of the thick blades.

(e)

If stacked blades do not fill the space, add blades or substitute blades until you form a snug fit

between surfaces being measured.

(f)

Remove blades, read thickness of each, and add the numbers together.

NOTE

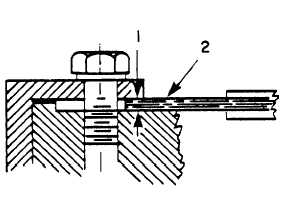

Item numbers below refer to figure 4-15, unless otherwise indicated.

Example:

One of the uses of a thickness gage is to measure the gap (1) needed between the traverse lock assembly and the turret

ring.

Figure 4-15. Traverse Lock Assembly

4-12

|