|

| |

TM 9-254

4-2.

Use of Gages - Continued

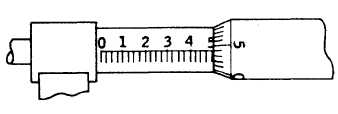

Example 4:(fig. 4-13)

0.500 inch - Largest numbered graduation on the revolution line.

0.000 inch - Number of unmarked graduations between 5 and the edge of the thimble.

0.004 inch - Number of graduations between 0 on the thimble and the revolution line.

0.504 inch - The final correct reading. In this example the edge of the thimble appears to

coincide with the 0.500 graduation on the barrel. If this were true the 0 line on the

thimble would coincide with the revolution line; hence, the last figure of the final

reading cannot be 0.

Figure 4-13. Micrometer Barrel Setting - .504 inch

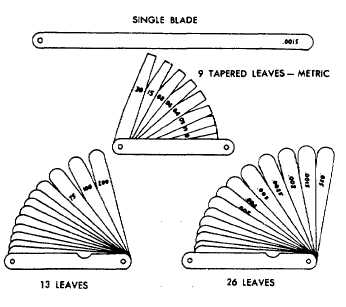

c.

Thickness Gage (fig. 4-14). The thickness gage, often referred to as a feeler gage, measures the clearance

or distance of separation between two surfaces that face each other.

(1)

The thickness gage contains several blades, each blade calibrated to a known thickness in thousandths

of an inch or in millimeters for metric sizes. Each of the blades is of a different thickness and each

blade has its thickness printed on the blade itself.

Figure 4-14. Thickness Gage - Blade Type

4-11

|