|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-1240-375-34&P

0100 00

3.

Record reading on deflection counter (1).

4.

Compare reading on deflection counter (1) recorded in step 1 with this reading. Reading of deflection

counter should have increased 95 0.5 mils.

5.

Repeat steps 2, 3, and 4 using the L-95 setting on correction counter (3).

Check that reading on deflection counter (1) has decreased 95 0.5 mils.

6.

Torque Inspection

1

4

3

2

1 fc 6 8 6

1.

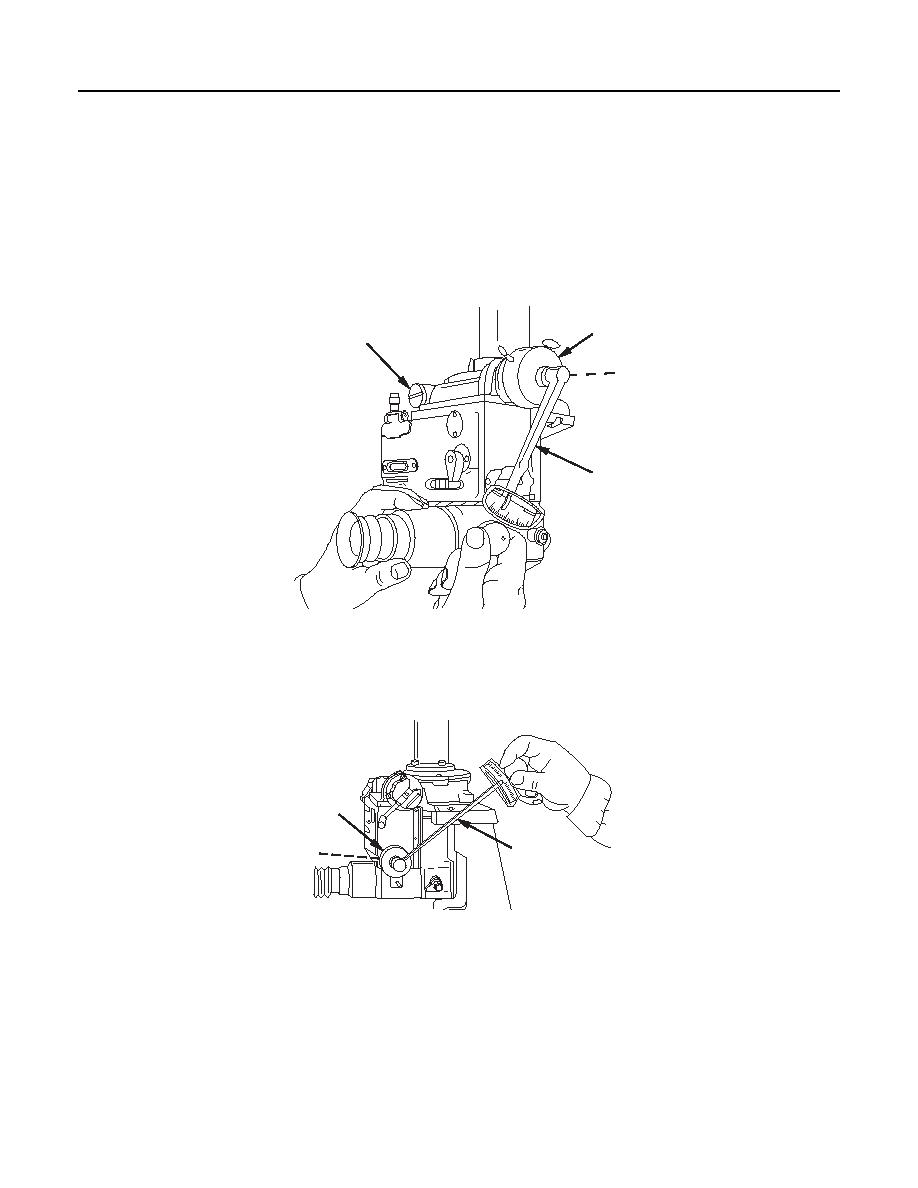

Place torque wrench adapter (1) on torque wrench (2). Place over azimuth knob (3).

2.

Move torque wrench (2) and observe readings. Torque must be between 3 in.-lb (0.34 N-m) and 8 in.-lb

(0.90 N-m). If torque cannot be met, tighten or loosen retainer (4).

5

6

7

1 fc 6 8 7

3.

Place torque wrench adapter (5) on torque wrench (6). Place over correction knob (7).

4.

Move torque wrench (6) and observe readings. Torque must be between 10 in.-oz (0.07 N-m) and

20 in.-oz (0.14 N-m). If torque cannot be met, return M137/M137A2/M137A3 telescope to depot

maintenance.

0100 00-29

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |