|

| |

TM 750-116

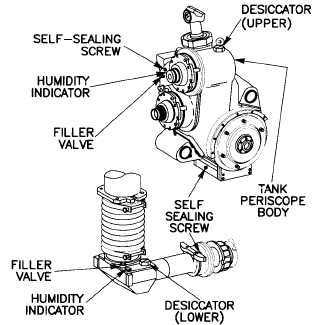

q. Periscope, M901 (fig 3-35).

NOTE

Desiccant must be replaced every time unit is

purged. Do not check pressure at any time oth-

er than during the pressurizing cycle. Loss of

pressure resulting from such attempts will

shorten the time between maintenance actions.

Refer to appendix A for listing of applicable

publications.

(1) Upper Section.

Pressurizing in excess of 10 psig (68.95 kPa)

can cause damage to seals.

(a) Remove desiccator by unscrewing container part

(hex head) from tank periscope body.

(b) Hold container part upright and remove slotted

cap of desiccator by turning counterclockwise using screw-

driver and discard old desiccant.

To prevent damage to tank periscope, purge

charging lines by blowing pressurized nitro-

gen through lines. This will remove any con-

tamination in lines.

(c) Close pressure regulator valve (CCW). Open

nitrogen tank valve and observe nitrogen tank pressure

gauge, indicating tank is pressurized.

(d) Remove dust cap on filler valve. Install hose

assembly and loosen self-sealing screws in both upper and

lower sections.

(e) Open pressure regulator valve (CW) to purge

pressure of 4-5 psig (27.5 to 34.4 kPa) on low pressure

gage. Check that nitrogen is being discharged from self-

sealing screw holes.

(f) Alternately open and close self-sealing screw

holes so one hole is open and another is closed every 15

minutes.

(g) Purge until humidity indicator is blue (approxi-

mately 30 minutes).

(h) Close pressure regulator valve (CCW).

(i) Remove desiccator from tank periscope body.

Remove slotted cap and install new desiccant.

(j) Lubricate preformed packing on desiccant cap

lightly with grease or silicone compound and install cap and

desiccator. Torque cap to 20 to 30 in lb. (2 to 3 Nm).

(k) Slowly open pressure regulator valve (CW) and

pressurize upper section for 10 seconds to value given be-

low for ambient air temperatures.

(l) Close nitrogen tank supply valve (CW) and re-

move hose assembly. Install dust cap on filler valve.

Ambient Air Temperature List

Air Temp.

Pressurize to:

Above +110°F (43°C)

4.0 psig

+85°F to +110°F (25°C to 43°C)

3.0 psig

+55°F to +85°F (13°C to 29°C)

2.0 psig

+30°F to +55°F (-1°C to 13°C)

1.0 psig

+5°F to +30°F (-15°C to -l°C)

0.5 psig

Below +5°F (-15°C)

0 psig

Figure 3-35 M901/M981 Tank Periscope

(2) Lower Section.

Pressurizing assemblies in excess of 10 psig

(68.95 kPa) can cause damage to seals.

(a) Remove desiccant cap and old desiccant from

desiccant container and install desiccant cap.

(b) Close pressure regulator valve (CCW). Open

main valve on nitrogen tank and observe nitrogen tank pres-

sure gage indicating tank is pressurized.

(c) Remove dust cap on filler valve and install valve

extension and hose.

(d) Remove l/4-inch upper and lower self-sealing

screws.

(e) Open pressure regulator valve (CW) to purge

pressure of 4-5 psig (27.5 to 34.4 kPa) on low pressure

gage.. Check that nitrogen is being discharged from self-

sealing screw holes.

3-16

|