|

| |

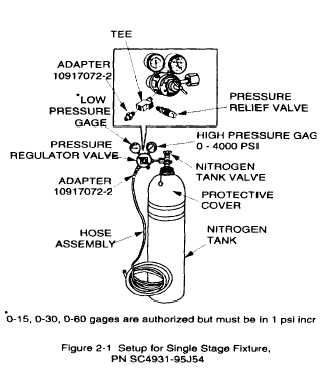

Figure 2-1.

TM 750-116

CHAPTER 2

GENERAL PROCEDURES

2-1. SCOPE. This chapter describes genera!

procedures for the setup of purging and charging

equipment time cycles.

2-2. SETUP OF PURGING AND CHARGING

EQUIPMENT, (figs. 2-1 and 2-2).

a. Setup for Single Stage Fixture(fig. 2-1)

(1) Obtain a tank of water pumped dry nitrogen and

remove threaded protective cover from the outlet of the

tank. Open tank valve momentarily to rid valve seat of

any foreign material.

(1.1) Remove the adapter from the regulator

install tee into the regulator. Install valve relief into

tee in the 3 o’clock position. install the adapter into

tee in the 6 o’clock position.

DO NOT DROP TANK OF COMPRESSED

NITROGEN GAS. WHEN USING IN CONFINED

AREAS, USE EXTREME CARE;

GAS COULD CAUSE ASPHYXIATION.

(2) Securely attach regulator to tank valve using ap-

propriate adapter supplied with purging kit if

necessary.

(3) Securely attach hose assembly to the adapter.

NOTE

When using regulator 11729749, adapter

10917072-2 is required to connect hose assembly to

low pressure to low pressure port of regulator.

(4) Close pressure regulator valve

counterclockwise (CCW) to the extreme closed

position.

(5) Open the nitrogen tank valve (CCW) slowly until

the maximum tank pressure is registered on the high

pressure gage.

NOTE

If pressure indicated is less than 100 psi, obtain

and use replacement tank.

(6) SIowly open pressure regulator valve clockwise

(CCW) until approximately 5 psi is registered on the low

pressure gage. Check for and eliminate any

interference; close pressure regulator valve (CCW).

(7) For bleed down procedures, refer to para 2-3a.

Change

1

2-1

|