|

|||

|

|

|||

|

Page Title:

TYPICAL FLANGED ANGLE HOSE GLOBE VALVE REPLACEMENT |

|

||

| ||||||||||

|

|

TM 55-1925-292-14&P

0016 00

3. Install the threaded globe stop check valve (figure 3, item 3) and the piping (figure 3, items 4 and 5) between

the unions (figure 3, items 1 and 2).

4. Tighten the unions (figure 3, items 1 and 2).

5. Perform the Follow-On Service procedure at the end of this work package.

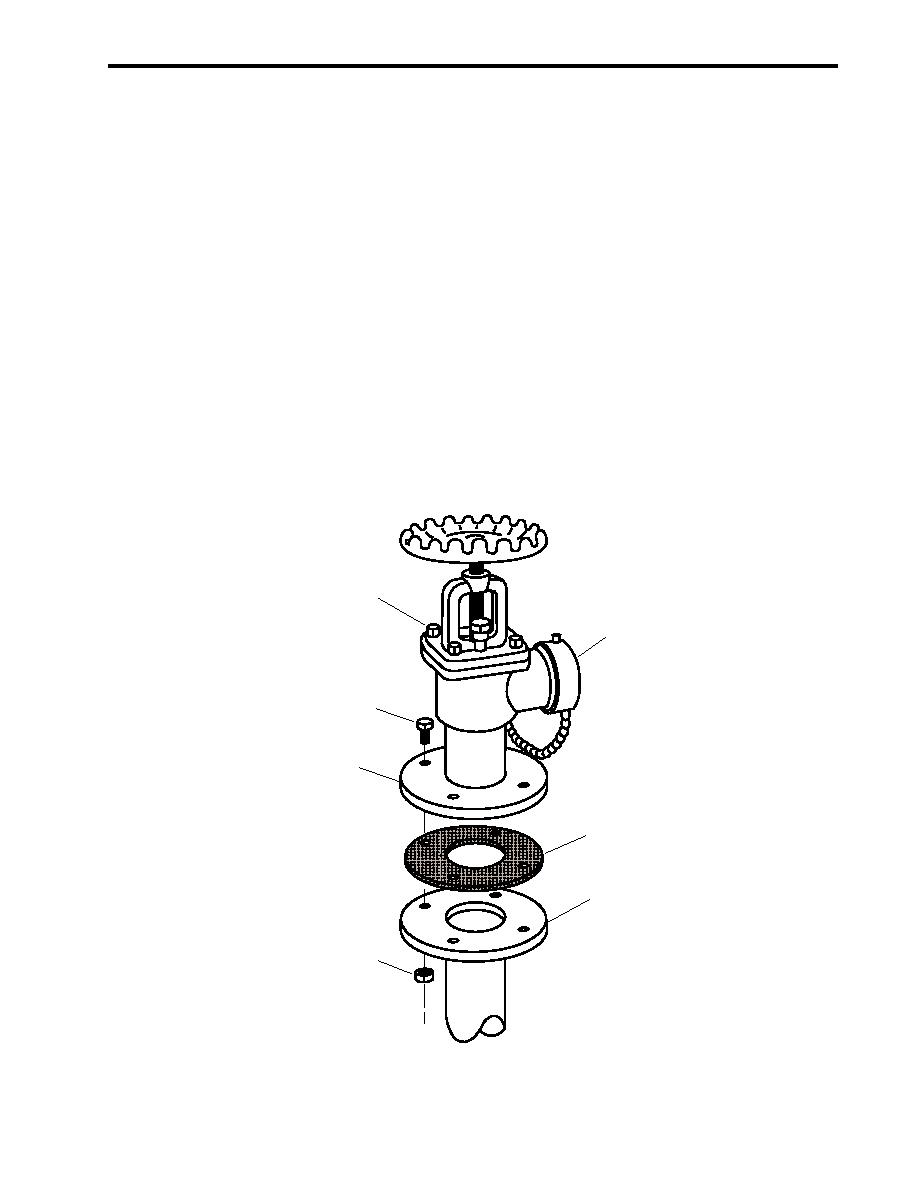

TYPICAL FLANGED ANGLE HOSE GLOBE VALVE REPLACEMENT

REMOVAL

1. Place a suitable drain pan under the cap (figure 4, item 1).

2. Remove the cap (figure 4, item 1) and partially OPEN the valve (figure 4, item 2) to vent any pressure or fluid

from the valve.

3. Place the suitable drain pan under the valve (figure 4, item 2).

4. Loosen, but do not remove, the four bolts (figure 4, item 3) and the four nuts (figure 4, item 4).

5. Allow time for any fluid to drain into the suitable drain pan.

2

1

3

6

5

7

4

Figure 4. Typical Flanged Angle Hose Globe Valve

0016 00-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |