|

|||

|

|

|||

|

Page Title:

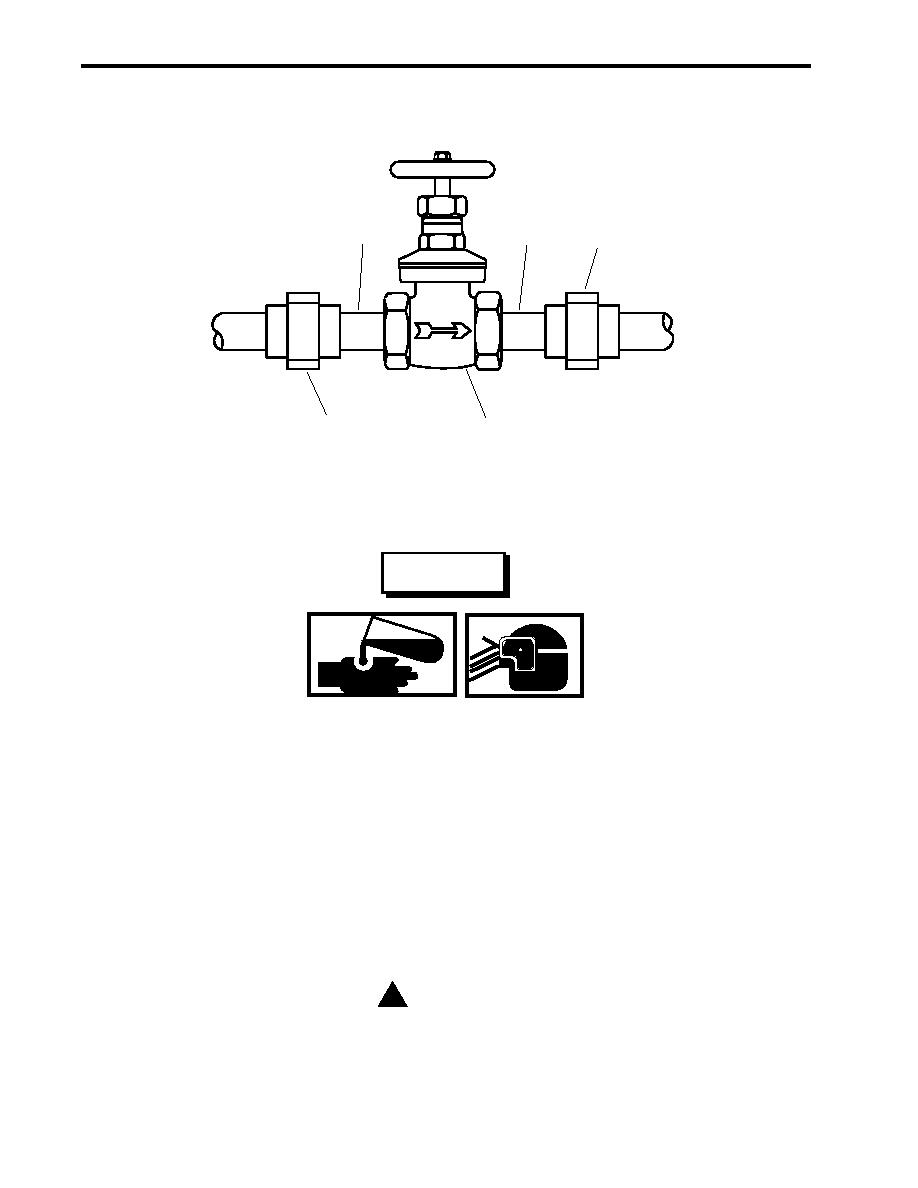

Figure 3. Typical Threaded Globe Stop Check Valve |

|

||

| ||||||||||

|

|

TM 55-1925-292-14&P

0016 00

5. Remove the attached piping (figure 3, items 4 and 5) from the threaded globe stop check valve (figure 3,

item 3). Retain the piping for installation.

4

5

1

2

3

Figure 3. Typical Threaded Globe Stop Check Valve

INSTALLATION

WARNING

Do not allow cleaning solvents to come in contact with unprotected skin or eyes.

Prolonged skin contact can cause illness or injury. Eye contact can cause seri-

ous injury. Always wear chemical protective gloves and goggles when handling

hydraulic fluid, engine oil, and cleaning solvents. Failure to follow these precau-

tions can result in illness or serious injury.

Removing components by means of wire brushing produces flying particles. These

particles can cause serious injury to personnel. Protective goggles, gloves, and

long sleeves must be worn at all times during wire brushing operations. Failure

to comply with this warning can result in serious injury to personnel.

1. Clean the threaded ends of the piping (figure 3, items 4 and 5) with a wire brush and apply antiseizing tape to

the threaded ends of the piping.

! CAUTION

Failure to use two wrenches while tightening pipe fittings, couplings, and valves may

cause damage to the valves, fittings, couplings, and piping. Always use two wrenches.

2. Install the piping (figure 3, items 4 and 5) in the threaded globe stop check valve (figure 3, item 3).

0016 00-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |