|

| |

TM 5-4210-233-14&P-1

5-43. FORWARD TANDEM AXLE AND DRIVE UNIT-Continued

(d) Install the same thickness spacer ring (15) in

output cage (1 3) as was removed at

disassembly. Install new retaining ring (14) in

groove in output shaft (16) to secure bearing

cones (1 7).

(e) The spacer ring (1 5) thickness controls the

end play of the output bearing.

(f)

Install yoke (11) on output shaft (69). Do not

install oil seal (12) at this time. Hold yoke (11)

in position and install nut (10) on output shaft (16).

Torque nut to 450 to 600 lb ft (618 to 815 N•m).

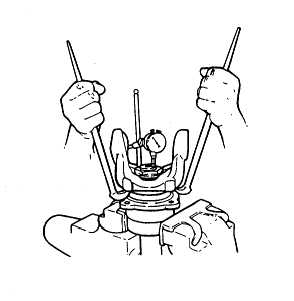

(g) Install a dial indicator with base of indicator on

mounting flange of bearing cage (13). Point of

indicator must touch yoke end of output shaft (1 6)

Adjust the dial indicator to zero.

(h) Use pry bars under yoke (11) and push

yoke (11) away from cage (13). Record reading on

the dial indicator. End play must be 0.001 to 0.004

inch (0.025 to 0.102 mm).

(i)

If reading is not within specifications, remove

nut (16) and yoke (11) and remove spacer

ring (15). Install a thinner ring to increase end

play and a thicker ring to decrease end play.

(j)

After end play has been adjusted to correct

specifications, remove nut (10) from shaft (16)

and remove yoke.

(66)

Apply axle lubricant (Item 45, Appendix E) to the inner bore of the output cage (13).

(67)

Place new oil seal (12) in cage (13) with flange of seal parallel with top of cage. Press oil seal (13)

into bore of output cage (13) until metal flange of seal contacts top of output cage (13).

(68)

After oil seal (12) is installed a gap of 0.015 to 0.030 inch (0.381 to 0.762 mm) can exist between

flange of oil seal (12) and cage (13). Use a feeler gauge to measure gap around flange to bearing

cage area. If the gap is more than 0.010 inch (0.254 mm) between the highest and lowest

measurement, remove and install a new oil seal (12) to obtain correct gap.

(69)

Clean the splines in the yoke (11) and on the output shaft (16). Apply lubricant (Item 45, Appendix

E) to splines.

5-319

|