|

| |

f.

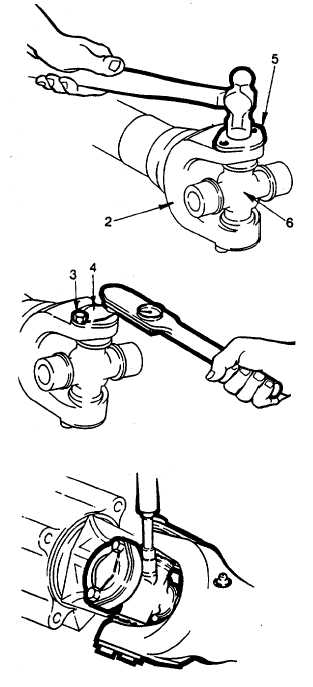

Installation of Universal Joints.

(1)

Install the cross yoke so that cross journals

are positioned in yoke lugs. Grease fitting

in cross must be toward shaft.

(2)

Install the bearing plate (5). Push journal of

cross (6) through the yoke lugs and into

needle bearing in bearing plate.

(3)

While supporting the cross to prevent

separation of cross and bearing, use a

hammer to lightly tap bearing plate (5) into

place in the yoke (2).

(4)

Install lockstrap (4) and capscrews (3).

Finger tighten capscrews.

(5)

Rotate

drive

shaft

yoke

to

facilitate

installation of the second bearing plate.

(6)

Carefully install bearing plate onto opposite

side of the cross (repeat procedure in steps

2 through 4).

(7)

Torque capscrews to 40 ft lb (54 Nm).

While tightening, move cross back and forth

to ensure that it does not bind in the needle

bearings.

(8)

Using a hammer and chisel, bend up the

lockstrap ears to secure capscrews.

(9)

Install drive shaft.

(10)

When all bearing plates are installed and

drive shaft is in place, lubricate the

universal

joints

until

high

temperature

grease (Item 15, Appendix E) is expelled

from all four bearing plate seals.

g.

Follow-on Maintenance.

(1) Connect batteries (see para 4-114).

5-33

|