|

| |

TM 5-4210-233-14&P-1

5-7. DRIVE SHAFTS, UNIVERSAL JOINTS AND YOKES - Continued

e.

Cleaning and Inspection.

(1)

Visually inspect exposed universal joint cross journals and needle bearings in bearing plates. Look

for defects caused by lack of lubrication and physical damage. If corrosion, pitting, universal wear or

missing bearing needles are evident, the universal joint must be replaced.

WARNING

Dry cleaning solvent P-D-680 is potentially dangerous. Avoid

repeated and prolonged breathing of vapors and skin contact

with the liquid. Do not use near open flame, arcing equipment

or other ignition sources. Always wear eye protection and

protective clothing. The flash point of P-D-680 is 100 to 138

deg. F (38 to 59 deg. C).

(2)

Using dry cleaning solvent (Item 3, Appendix E) and a brush, wash universal joint crosses and yokes.

Do not attempt to disassemble or wash bearing plates.

WARNING

Death or serious injury could occur if compressed air is directed

against the skin. Do not use compressed air for cleaning or

drying unless the pressure is/has been reduced to 30 psi (2.11

kg/cm2) or less. When working with compressed air, always use

chip guards, eye protection and other personal protective

equipment.

(3)

After washing, dry the components using compressed air.

(4)

Apply a small amount of high temperature grease (Item 15, Appendix E) to each bearing plate needle

bearing.

(5)

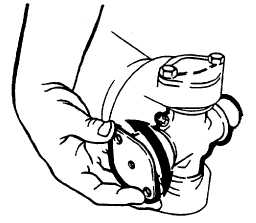

Install and test needle bearings on cross journals as shown. The movement must be smooth and

resistance free.

(6)

If any component is failing, the complete universal joint must be replaced.

5-32

|