|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-233-14&P-1

5-51. HOIST CYLINDERS - Continued

WARNING

Death or serious injury could occur if unauthorized

or unnecessary personnel are in the hoisting area.

Permit only personnel actually engaged in the

hoisting operation to be near the vehicle and

hoisting equipment. All instructions for the hoisting

operations must come from one authorized person.

WARNING

Injury to personnel or damage to equipment could

occur from improper hoisting. Hoist the load slowly

to avoid tearing out lifting eye assemblies, slipping

slings or load shift. Do not jerk the load or swing it

from side-to-side when hoisting.

This places

additional stress on hoisting components which can

cause failure and loss of load. Be sure hoisting

equipment is on solid footing and is suitable for the

size of the load. Watch boom angle and overhead

clearance when hoisting.

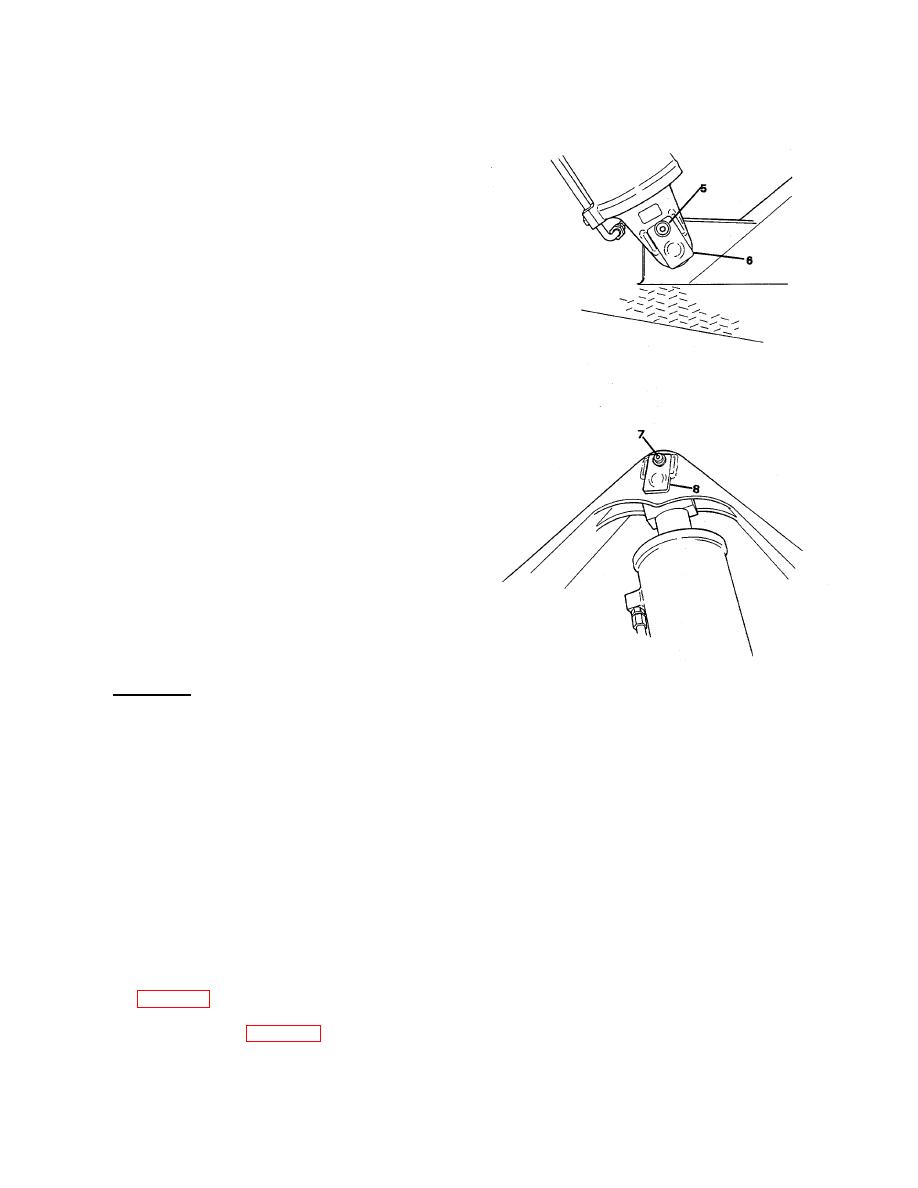

(5) Remove screws (5) and pin (6) from

cylinder.

(6) Lift lower end of cylinder away from

support.

(7) Remove screw (7) and pin (8) from

cylinder.

(8) Remove cylinder.

b. Installation.

(1) Install upper end of cylinder between

supports and install pin (8) and screw (7).

(2) Install pin (6) and screw (5) in lower end of

cylinder.

(3) Install hose (4).

(4) Install new O-ring between block (1) and

cylinder (2) and attach block (1) to cylinder

(2) with three screws (3).

(5)

Raise and lower ladder several times to

remove air from cylinder.

(6) Check oil level in the hydraulic oil tank (see

(7) Bed ladder (see para 2-14).

5-336

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |