|

|||

|

|

|||

|

Page Title:

REAR TANDUM AXLE AND DIFFERENTIAL |

|

||

| ||||||||||

|

|

TM 5-4210-233-14&P-1

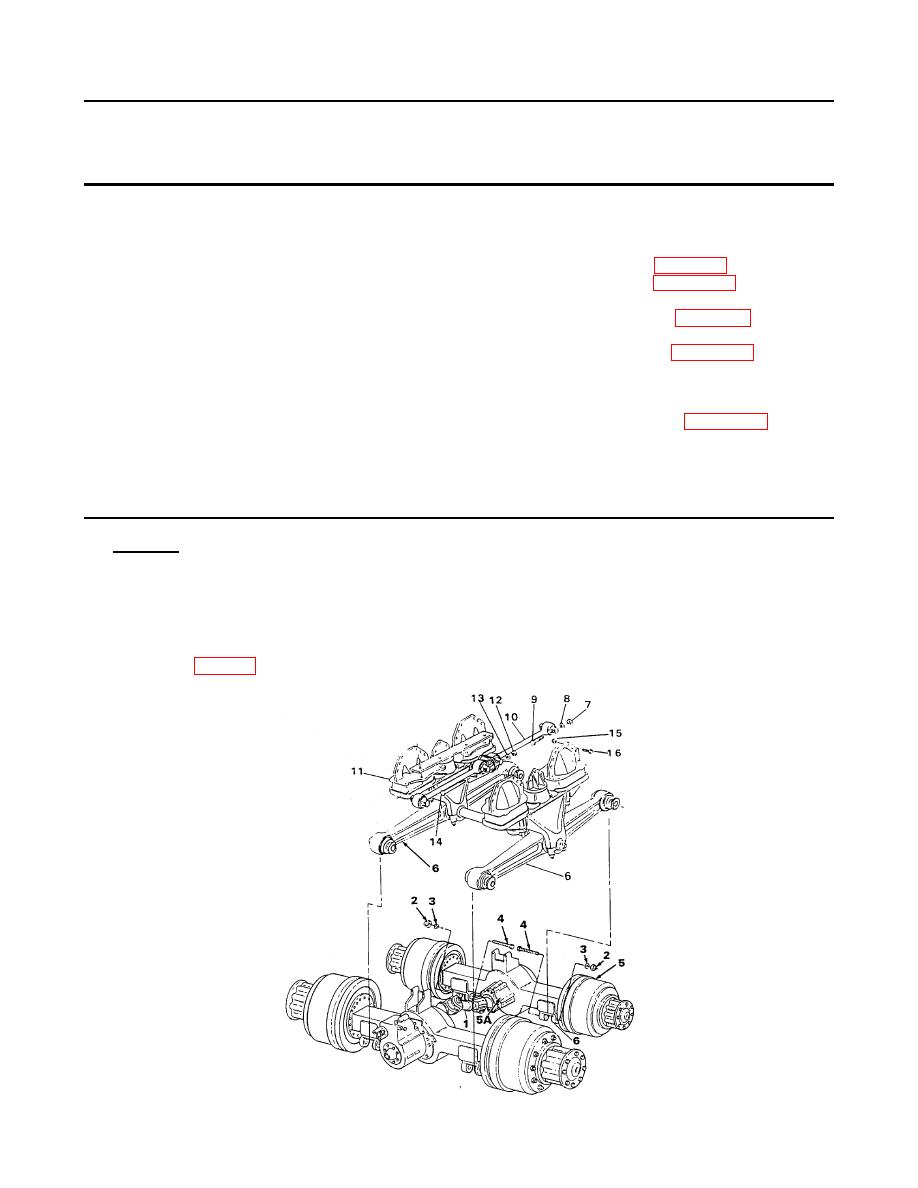

5-42. REAR TANDUM AXLE AND DIFFERENTIAL

This task covers:

a. Removal

d. Assembly

b. Disassembly

e. Installation

c. Cleaning and Inspection f. Follow-on Maintenance

TOOLS REQUIRED:

PERSONNEL REQUIRED - 2

Tool Kit, General Mechanics, Automotive

(Appendix B, Section 111, Item 1)

EQUIPMENTCONDITION

Tool Kit (Item 4)

Main Engine Shutdown (see para 2-12.)

Carrier Stand (Item 85, Appendix B, Section 111)

Batteries Disconnected (see para 4-114.)

Rear Tandem Axle and Differential

MATERIALS/PARTS REQUIRED

Brake Chambers Removed (see para 5-34.

)

Engine Oil (OE) (Item 20, Appendix E)

Rear Tandem Axle and Differential

Dry Cleaning Solvent (Item 3, Appendix E)

Slack Adjusters Removed (see para 4-146.)

Silicone Gasket Material (Item 35, Appendix E)

Rear Tandem Axle and Differential

Oil, Gear (Item 45, Appendix E)

Brake Shoes and Drums Removed (see para

Cord (Item 55, Appendix E)

5-36 and 5-37.)

Tags, Identification (Item 32, Appendix E)

Tires and Wheels Removed (see para 4-143.)

Compound, Retaining - Loctite (Item 7, Appendix E)

Marking Compound (Item 56, Appendix E)

Oil Seals (Figure 165, Appendix F)

Bearing Cones (Figure 165, Appendix F)

Bearing Caps (Figure 165, Appendix F)

a. Removal.

(1)

Place chocks under front wheels. Use a suitable jack or hoisting equipment to raise truck high enough

to remove axle.

(2)

Place sufficient blocking under truck frame to safely support truck during axle removal.

(3) Refer to para 5-7 and disconnect inter-axle drive shaft (1) from rear tandem axle differential (5A).

5-255

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |