|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-233-14&P-1

4-143. TIRES AND RIMS

THIS TASK COVERS:

a.

Removal

c.

Follow-on Maintenance

b.

Installation

TOOLS REQUIRED

EQUIPMENT CONDITION

Tool Kit, General Mechanics, Automotive

Ladder in Transport Position (see para 2-12.)

(Appendix B, Section III, Item 1)

Main Engine Shutdown (see para 2-12.)

APU Shutdown (see para 2-16.)

Shop Equipment, Automotive

Batteries Disconnected (see para 4-114.)

Maintenance and Repair

(Appendix B, Section 1II, Item 4)

1 0 Ton Hydraulic Jack

Jack Stands

a. Removal.

WARNING

Wheel and tire are heavy; 257 lb (1 17 kg). To avoid personal

injury, use care when removing.

NOTE

Left-side wheels have left-hand nuts, right-side wheels have

right-hand nuts. Correct nuts must be reinstalled.

(1) Locate 10 ton hydraulic jack beneath axle just inboard of the wheel that is to be removed.

(2) Apply truck parking brake and chock both wheels of other axle.

(3) Raise jack until tire clears ground.

(4) Adjust for proper height and place jack stand beneath axle. Lower jack until jack stand takes weight of

truck. Tire must be clear of ground when axle rests on jack stand. (If not, repeat steps 3 and 4 raising

jack stand by one notch until it is properly adjusted).

(5) Using wheel brace or air operated wrench, remove wheel nuts completely and pull wheel off axle studs.

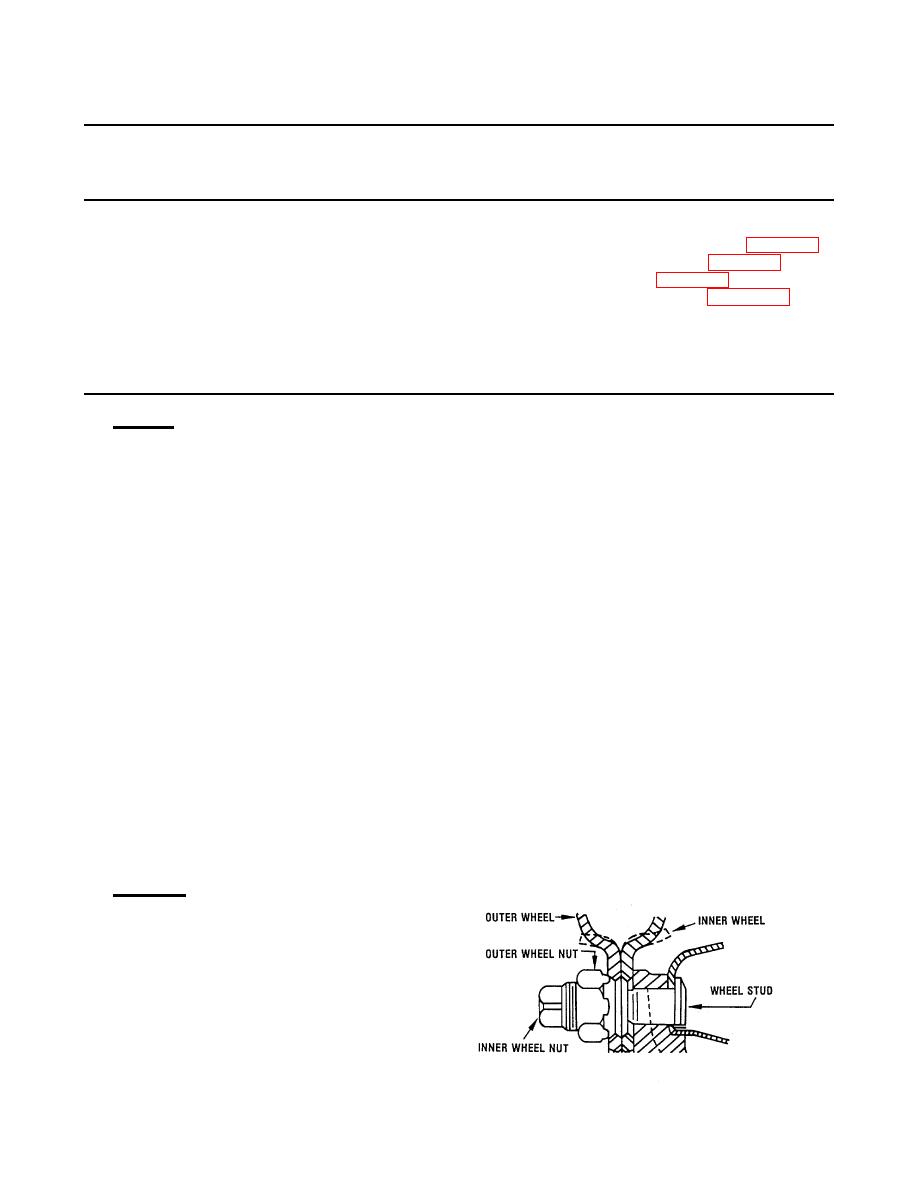

Take care not to damage stud threads. If necessary to remove inner sheel, remove inner wheel nuts.

(6) Place wheel lift truck beneath wheel and attach safety chain.

b. Installation.

(1) Check all parts for damage. Insure that

studs, nuts and mounting faces of hub

and wheels are sound, clean and free

from grease. Clean hub surface with

wire brush if scale is present. Replace

any damaged parts.

4-414

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |